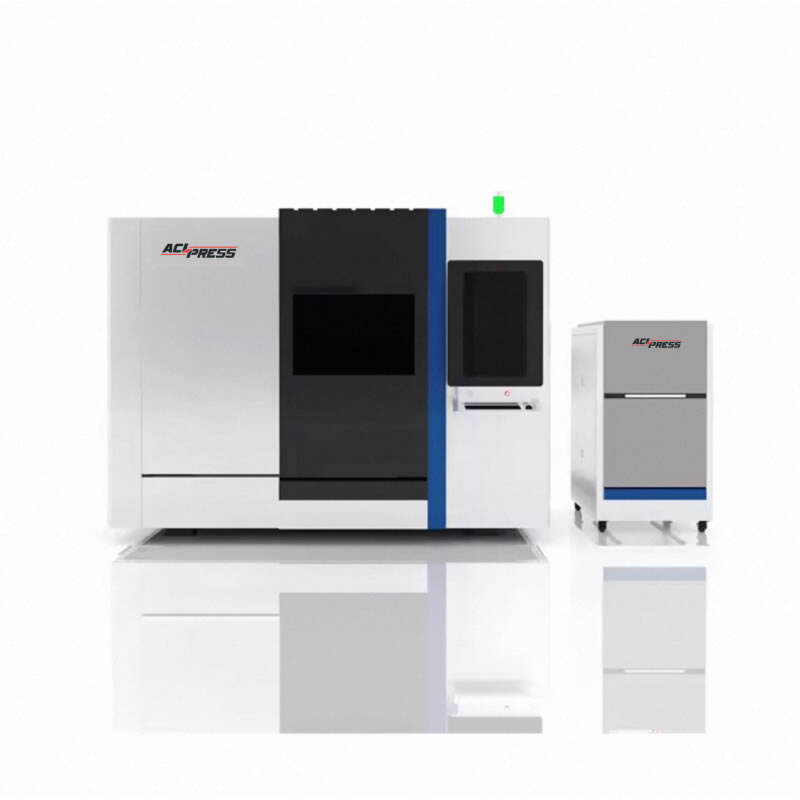

Performances of CNC press brake machine

The bending machine's CNC performance is demonstrated in the following ways:

Accuracy: The CNC bending machine (CNC press brake machine) is known for its high accuracy in bending. Equipped with advanced control systems and sensors, it allows precise control over the bending angle, position, and pressure, enabling high-precision bending operations.

Repeatability: CNC bending machines can achieve highly repeatable machining. Even during production runs and mass production, they can maintain consistent machining quality and dimensional accuracy.

Flexibility: The CNC bending machine can be swiftly switched and adjusted to meet various process requirements. By modifying the program parameters, it is possible to achieve bending operations with different angles, radii, and lengths, thereby accommodating diverse workpiece demands.

Degree of automation: The CNC bending machine can automatically complete multiple bending operations, reducing the need for manual intervention and labor intensity. The operator only needs to input the parameters and procedures, and the machine can automatically carry out the bending, thereby enhancing production efficiency.

Programming flexibility: CNC bending machines use programming control to perform flexible programming operations based on demand. By writing a bending program, various complex bending shapes and process requirements can be achieved to meet the processing needs of different workpieces.

Digital monitoring: CNC bending machines typically come equipped with a digital monitoring system that allows full-time checking and display of various processing parameters, including position, speed, pressure, etc. This system enables operators to monitor production status and diagnose faults in real time, thereby enhancing production efficiency and equipment reliability.

Overall, CNC bending machines are essential equipment in modern industrial production due to their high precision, repeatability, flexibility, automation, programming flexibility, and digital monitoring capabilities.

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TR

TR