CNC Electro Hydraulic Bending Machine

The CNC electric hydraulic bending machine from ACLPRESS offers high-precision, high-efficiency, and high-reliability bending solutions. Additionally, it possesses intelligent features and user-friendly design, catering to the requirements of modern manufacturing for efficient and high-quality production.

1. High control accuracy ensures precise operation.

2. Fast response speed is crucial for optimal performance.

3. Smooth operation is essential for seamless functionality.

4. High output power enhances overall productivity.

5. Flexible signal processing allows for versatile applications.

6. Easy realization of feedback for diverse parameters is advantageous.

7. Enhancing industry production efficiency is a key objective.

- Features

- Details

- Specifications

- Inquiry

- Related Products

The ACLPRESS electro hydraulic servo CNC bending machine utilizes a servo motor as an actuator and integrates a numerical control system grating ruler feedback data to regulate the flow ratio of the main oil cylinders on both sides, enabling synchronous movement of the slider.

1. The electro-hydraulic servo CNC bending machine utilizes a hydraulic convex automatic compensation system to address the impact of slider deformation on workpiece quality during bending. The compensation amount is automatically adjusted by the numerical control system, ensuring convenience and accuracy.

2. The electro-hydraulic servo CNC bending machine features a comprehensive rear material holding mechanism that allows for control of multiple rear material shafts. Pivotal components in the rear material mechanism, such as guide rails, screws, and bearings, are imported originals to maintain precision.

3. The structure of ACLPRESS electro-hydraulic servo CNC bending machine body is welded as a whole, facilitating transportation and processing while guaranteeing machine tool accuracy.

4. The body, slider, and other vital components of ACLPRESS electro-hydraulic servo CNC bending machine undergo analysis using ANSYS finite element analysis software to verify machine tool reliability.

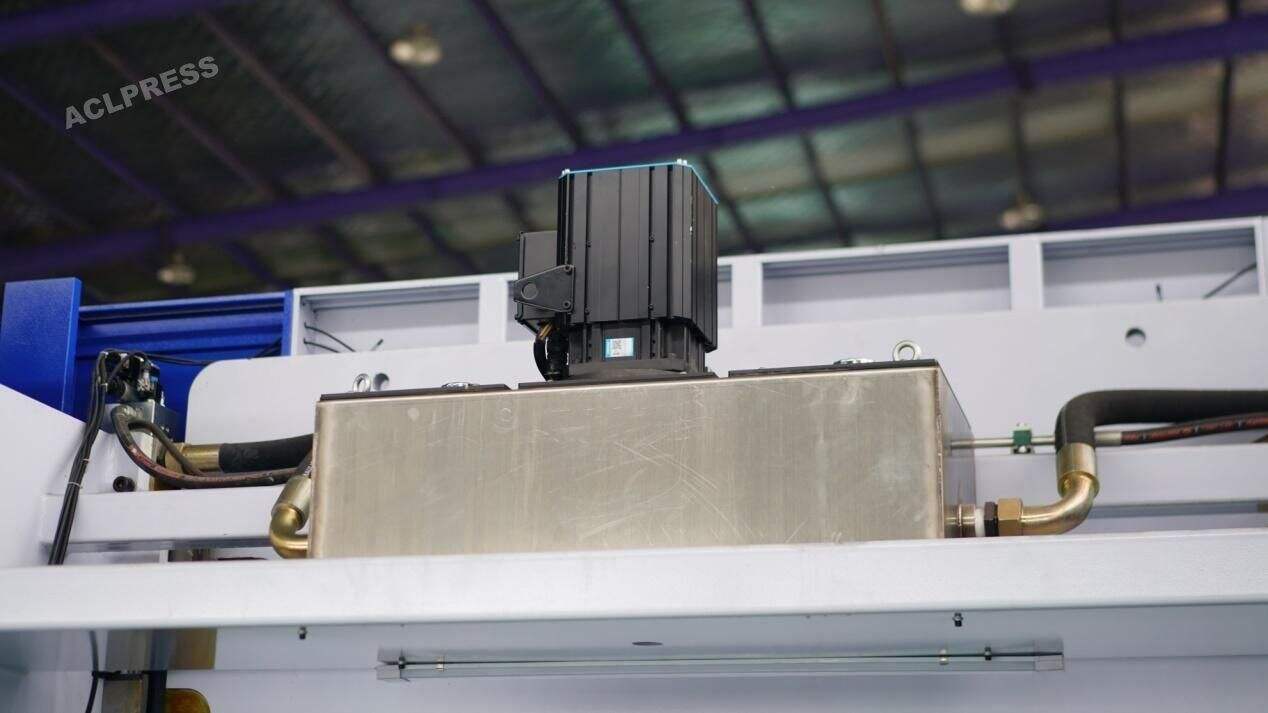

5. The hydraulic system of ACLPRESS electro-hydraulic servo CNC bending machine integrates a control system imported from Germany, reducing pipeline installation, enhancing machine tool stability, and an aesthetically pleasing and straightforward design.

Rear Blocking System for A Quicker And More Accurate Positioning

By adopting steel structure welding with high rigidity, servo motor, ball screw, and linear guide, this machine can automatically adjust the tool to the accurate position required for processing parts. That's how it can ensure precise positioning of the workpiece, producing workpieces that meet the specified requirements.

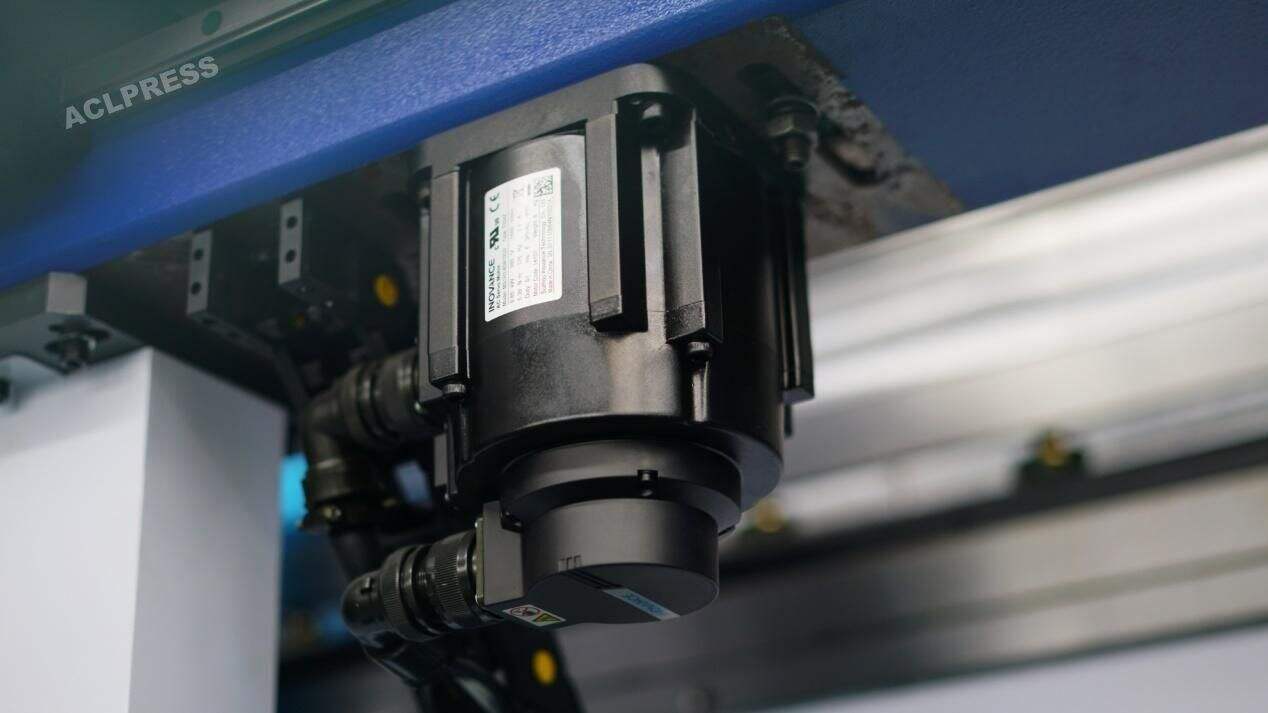

Servo Motor

Using servo motors as the primary power source for hydraulic pumps can result in energy savings of approximately 40%. Additionally, this can lead to an overall efficiency improvement of around 7-20%. Moreover, servo motors can help reduce the oil temperature by approximately 10-20℃.

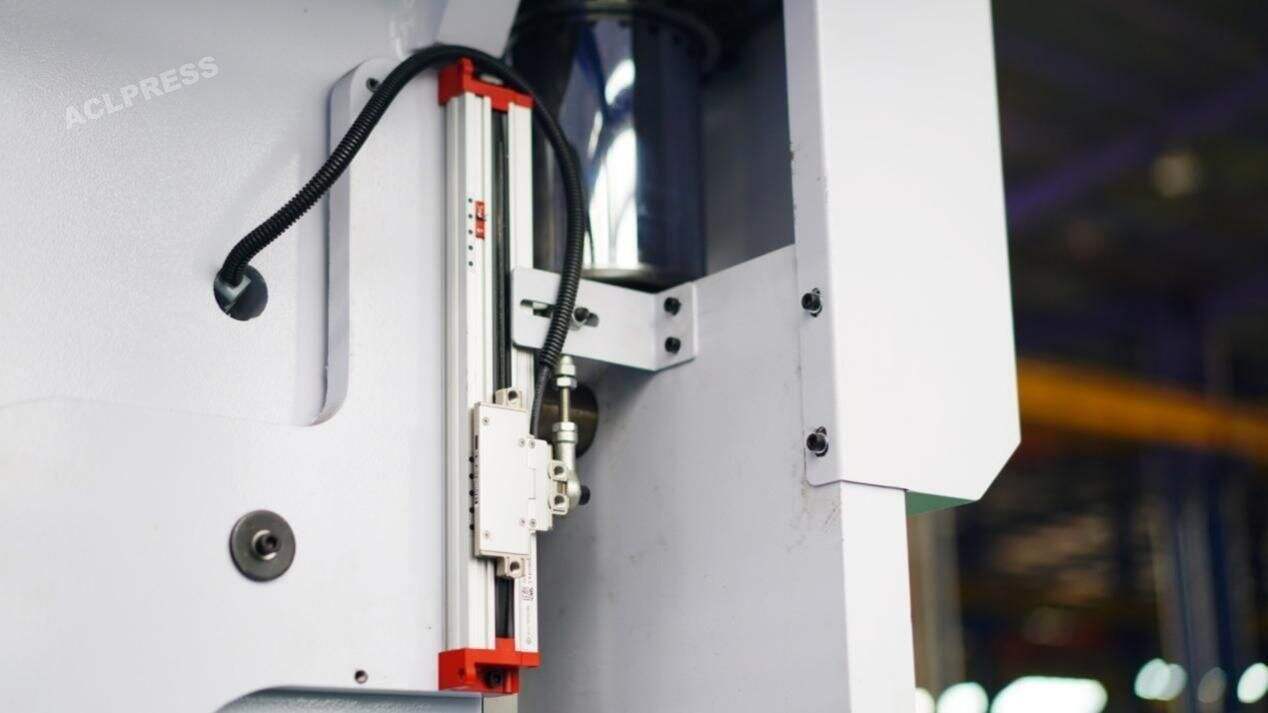

Grating Ruler

The grating ruler can accurately measure deformation and provide feedback compensation, effectively preventing collisions and interference between the workpiece and the grating ruler.

Mobile Front Support

The movable front support rack moves along a straight guide rail and can stop at any position, assisting you in your bending work and making it comfortable and efficient.

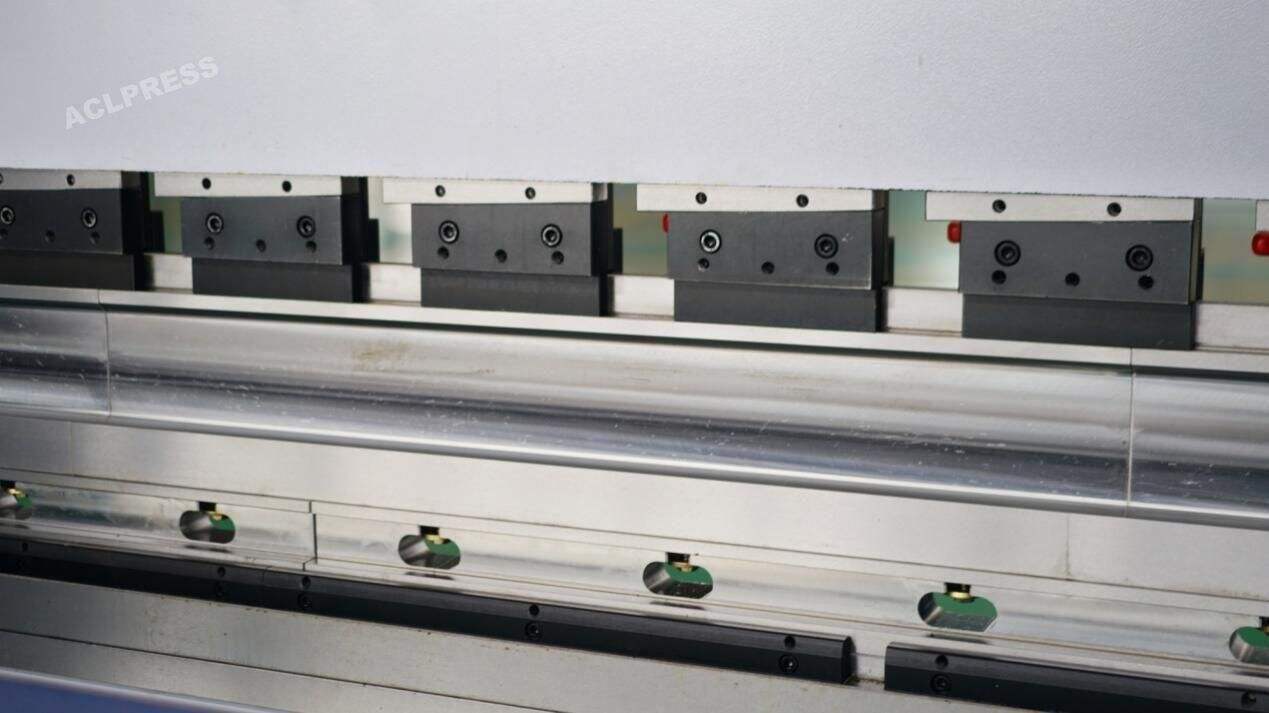

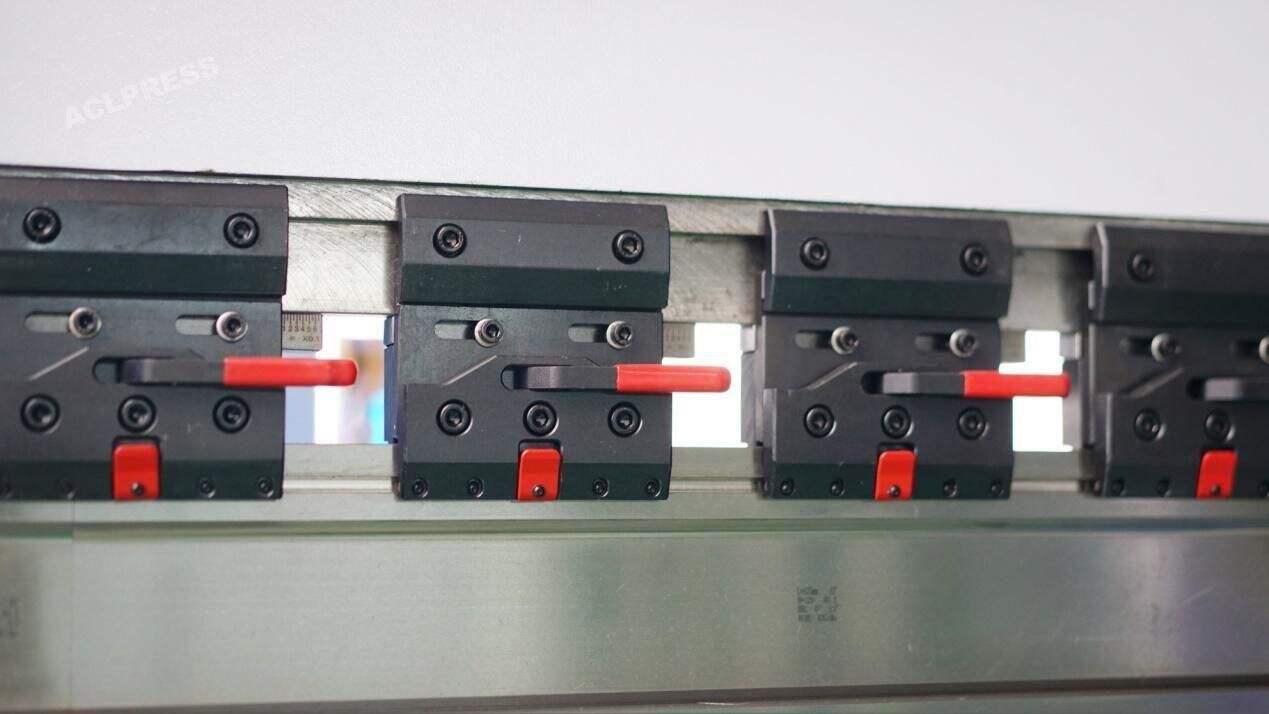

Fast Mold Clamp

The precision quick clamping device facilitates the convenient replacement of press brake molds, reducing labor costs, saving press brake setup time, improving production efficiency, and increasing operator safety

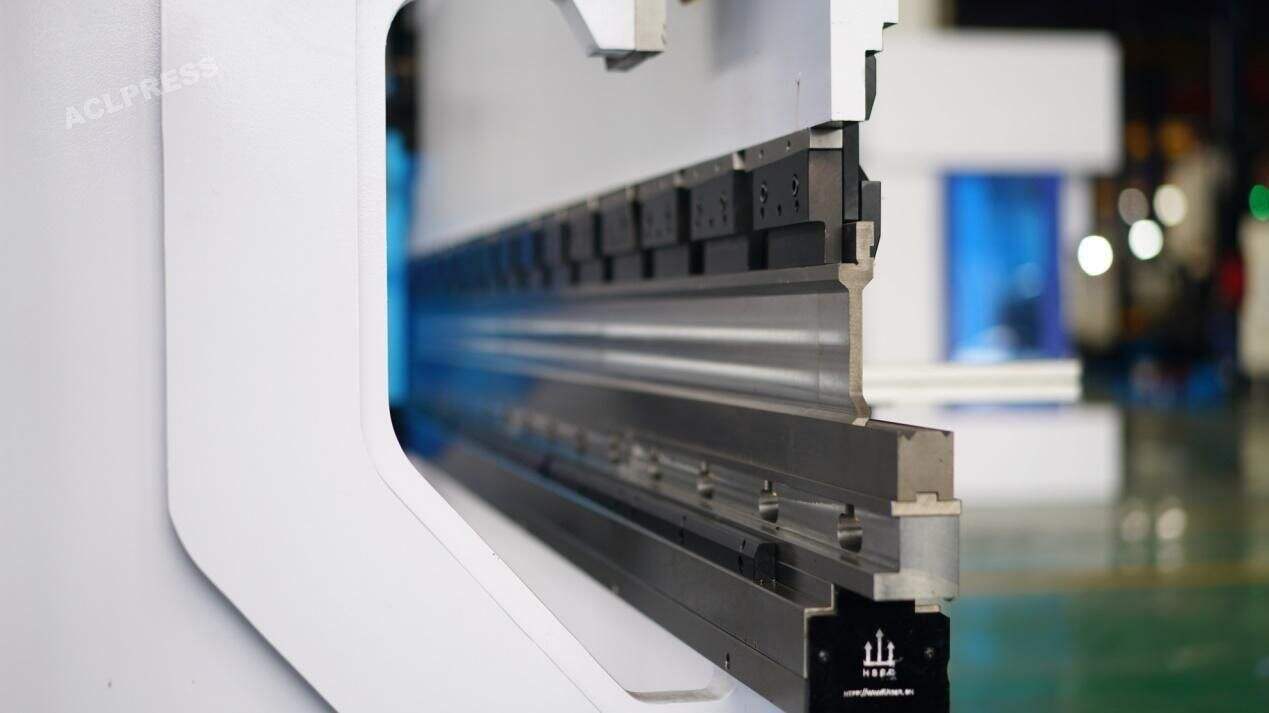

High-quality CNC Press Brake Tools

Precise, well-heated, and durable.

DA-53T

"Hot-key” touch navigation.

10.1" high-resolution colour TFT.

Up to 4 axes (Y1,Y2 + 2 aux axes).

Crowning control.

Tool/material/product library.

Servo and frequency inverter control.

Advanced Y-axis control algorithms for closed-loop as well as .

open-loop valves.

TandemLink (option).

USB memory stick interfacing.

Profile-T offline software.

DA-58T

2D touch graphical programming.

15" high-resolution TFT true color display.

Bending process calculation.

Deflection compensation control.

Servo and drive control modes.

Advanced Y-axis control algorithm, you can control the closed-loop valve can also control the open-loop valve.

USB interface.

DA-66T

2D Touch graphical programming.

3D Product graphical simulation display.

17" High-resolution TFT Color Display.

Full Windows application package.

Compatible DELEM modular structure.

USB, Peripheral Interface.

User program applications under a multi-tasking environment.

Angle-detecting sensor interface.

DA-69T

3D and 2D graphical touchscreen programming mode.

3D visualisation in simulation and production.

17″high resolution color TFT.

Full Windows application suite.

Delem Modusys compatibility (module scalability and adaptivity).

USB, peripheral interfacing.

Open system architecture.

Sensor bending &correction interface.

CybTouch12

12 "color LCD, touch screen, icon recognition function;

The "EasyBend" page is processed with easy single bending.

The fully efficient bending programming can meet the needs of mass production and processing.

Automatically calculate bending angle, main pressure, and deflection compensation;

Automatic calculation of bending data;

Automatic calculation of pressure and deflection compensation; automatic calculation of upper die depth;

Angle, rear blocking correction, 2D graphics programming;

Automatically simulate the bending steps and provide the optimal bending solution.

CybTouch 15

PS(Cybelec)

15 "modern streamlined glass mirror touch screen, which can be used with gloves.

User-friendly man-machine interface, intuitive programming, and easy-to-set navigation function (automatic optimization of machine parameters).

2D finger drawing programming (touch file) and accurate 2D program creation.

Automatic bending step calculation.

Easybend page to facilitate single-part bending.

Larger storage capacity.

Internal backup and storage functions.

Wireless communication function for diagnosis and upgrade by laptop.

VIS-S875 (Italy ESA)

21.5-inch multi-touch screen design.

Supports for multi-touch applications.

Borderless, simple but powerful.

Supports fingertip workpiece design.

Supports tool shape import (.dxf file).

Supports tool library management.

Supports the management of tools and mold fixtures.

Supports data angle measurement system.

Supports ESA 3D bending software.

Equipped with standard industry 4.0 Modbus TCP interface.

KV-S640 (Italy ESA)

15” touch screen.

Top-level performances for machines up to six axes.

Widescreen for a full graphic interface.

Supports automatic bending process calculation.

Supports automatic compensation control.

Dynamic crowning is available.

Direct connection to support the installation of the angle measurement device.

| Model | Poles distance(mm) | Throat depth(mm) | Slider stroke(mm) | Max height(mm) | Power(kw) | Weight(kg) | Demension (mm) |

| 63T/2500 | 1900 | 250 | 100 | 320 | 5.5 | 4000 | 2500x1300x2210 |

| 63T/3200 | 2560 | 250 | 100 | 320 | 5.5 | 4800 | 3200x1300x2210 |

| 80T/2500 | 1990 | 300 | 100 | 320 | 7.5 | 5000 | 2500x1400x2300 |

| 80T/3200 | 2560 | 320 | 100 | 350 | 7.5 | 6000 | 3200x1500x2300 |

| 80T/4000 | 3200 | 320 | 100 | 350 | 7.5 | 7000 | 4000x1500x2400 |

| 100T/2500 | 1990 | 320 | 120 | 350 | 7.5 | 6000 | 2500x1600x2400 |

| 100T/3200 | 2600 | 320 | 120 | 400 | 7.5 | 6800 | 3200x1600x2600 |

| 100T/4000 | 3200 | 320 | 120 | 400 | 7.5 | 8000 | 4000x1600x2600 |

| 125T/3200 | 2600 | 320 | 120 | 400 | 7.5 | 7000 | 3200x1600x2600 |

| 125T/4000 | 3200 | 320 | 120 | 400 | 7.5 | 8500 | 4000x1600x2600 |

| 160T/3200 | 2580 | 320 | 120 | 460 | 11 | 10000 | 3200x1700x2700 |

| 160T/4000 | 2900 | 320 | 160 | 460 | 11 | 11000 | 4000x1700x2800 |

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TR

TR