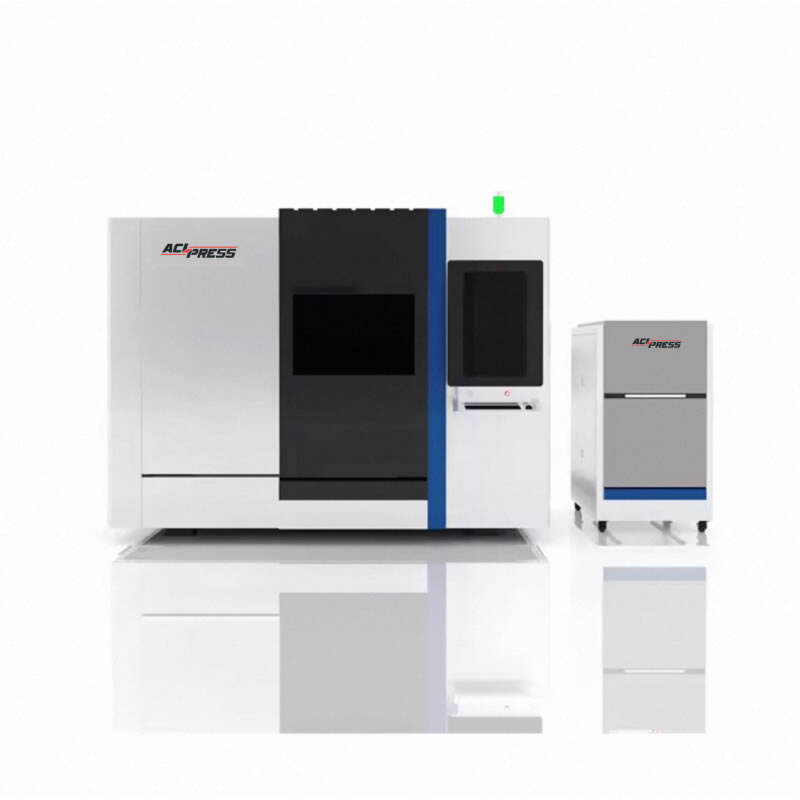

Double Tables Laser Cutting Machine

Optical fiber exchange table large encirclement laser cutting machine by ACLPRESS

1. The focus point is small, and the cutting lines are precise.

2. The power consumption of the entire machine is only 20-30% of that of similar CO2 laser-cutting machines. It can cut various metal sheets using air.

3. User-friendly man-machine control interface, modular design, and automatic identification of mainstream drawing files.

4. Surrounding design includes fully enclosed external protection, significantly enhancing cleanliness in the working environment and safety, and meeting the CE standard.

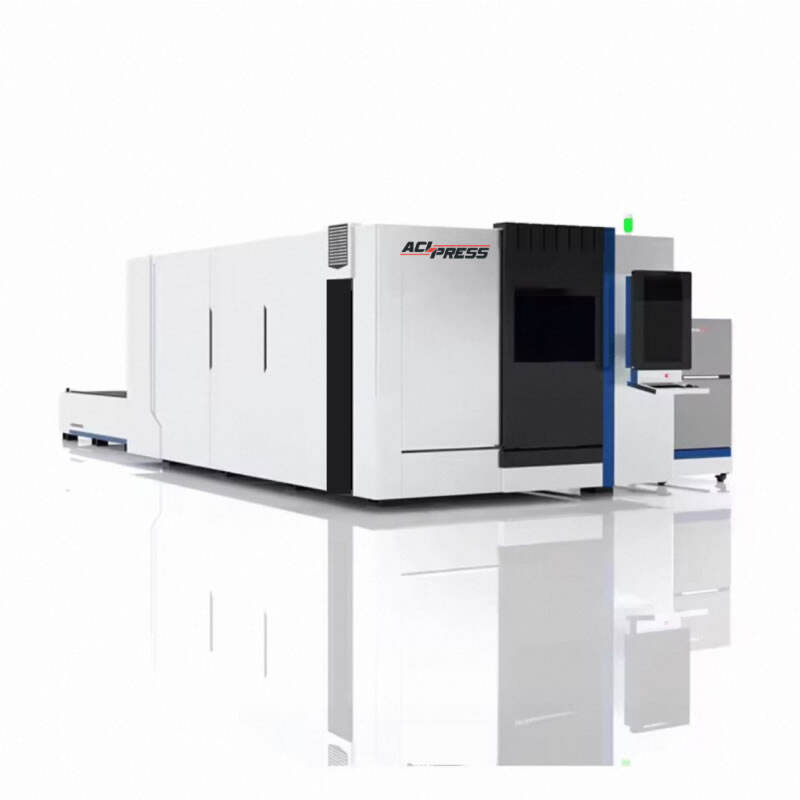

5. Equipped with imported AC servo drive, fully sealed gear rack drive, and reliable linear rail guidance.

6. Gantry structure, high-damping bed body, and aluminum alloy extruded beam, capable of withstanding high speed and acceleration.

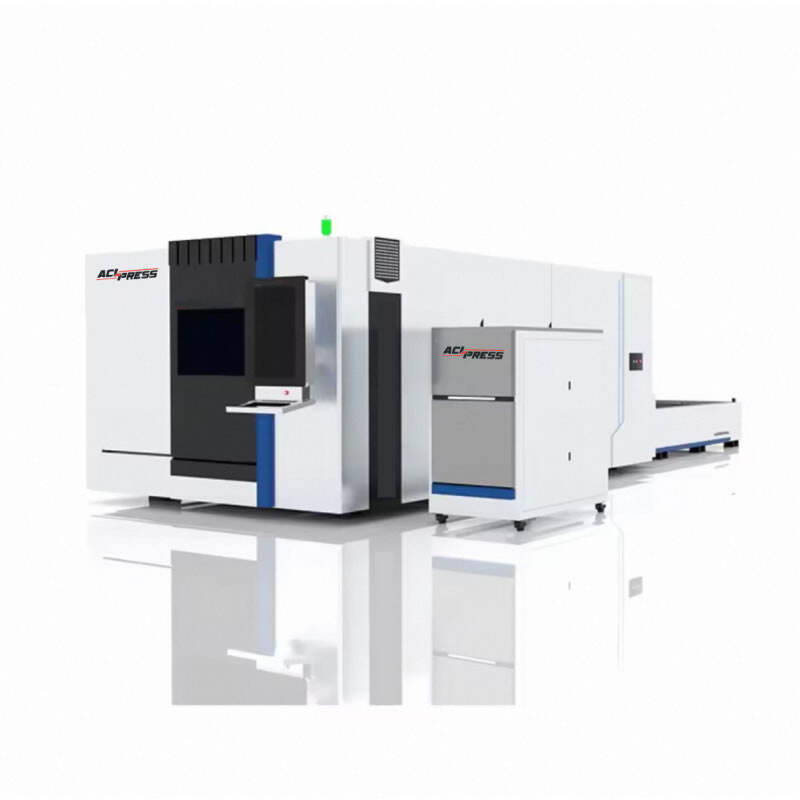

7. Utilizes modern industry-leading platform switching devices, enabling dual-platform swap within 10 seconds.

8. Equipped with a standard lPG fiber laser generator with a service life of 100,000 hours, virtually maintenance-free. The laser cutting head is fitted with an imported capacitor contactless height tracking system to ensure the cutting focus position and prevent collisions with the processed sheet.

- Features

- Details

- Specifications

- Inquiry

- Related Products

1. Fully enclosed large envelope design, intimate care of the operator’s health; green environmental protection without pollution.

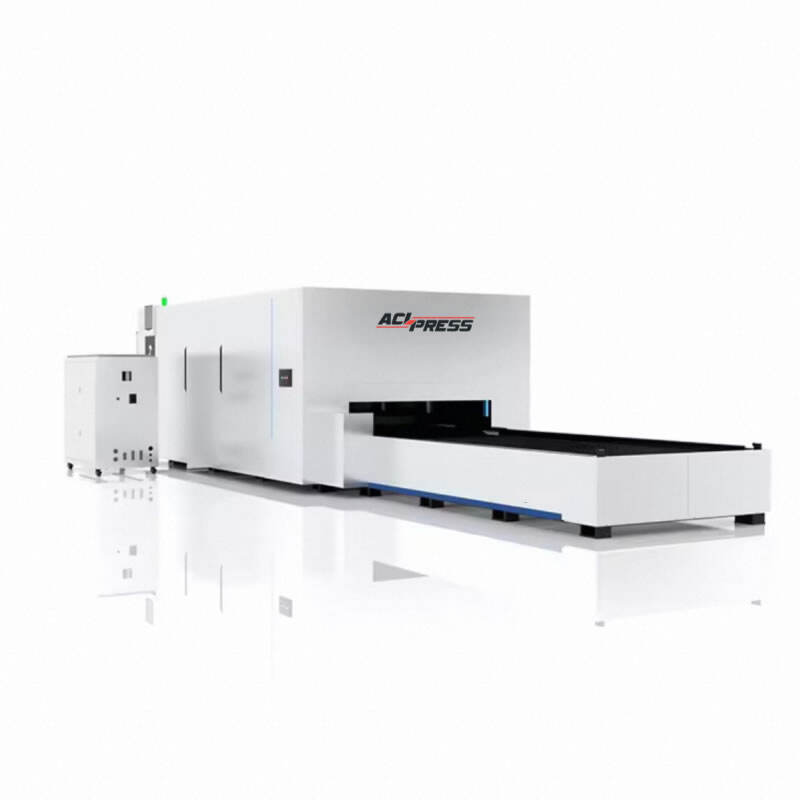

2. Front and rear double platform exchange type design, shorten the standby time and improve the working efficiency by 30%.

3. Adopt gantry structure, the bed is welded as a whole, the whole machine runs smoothly and has good rigidity.

4. All kinds of components are made of famous brands at home and abroad, with high precision, high speed, stable and durable performance.

Laser Cutting Head

Three protective lenses efficiently protect the collimating and focusing lenses. Bidirectional optical water cooling efficiently extends the continuous working time.

No manual focusing is required as the software automatically adjusts the focusing lens, simplifying the operation and making it ten times faster than manual speed.

Various stable qualified brands of laser heads are available for ACL laser.

Switching to a new platform enhances processing efficiency. By utilizing an exchange work platform, the workbench achieves rapid and stable communication, increased rigidity, and higher accuracy. This results in saved feed time, with an exchange time of 7 seconds, ultimately enhancing work efficiency.

Electric Cabinet

Separate electric cabinet with air conditioning.

Hanli Brand Industrial Chiller

Hanli Water Chiller.

Great Brand Fiber Laser

MAX & Raycus & IPG Brand Laser Source.

Higher electro-optical conversion efficiency, excellent reliability, modularity, easy maintenance, and low, and high reflection resistance.

It adopts an air-cooled compact structure design with a semiconductor fiber as the laser generation medium, which is environmentally friendly. The mechanical structure is simple, and the optical path is constant, requiring almost no maintenance, and ensuring stable cutting performance.

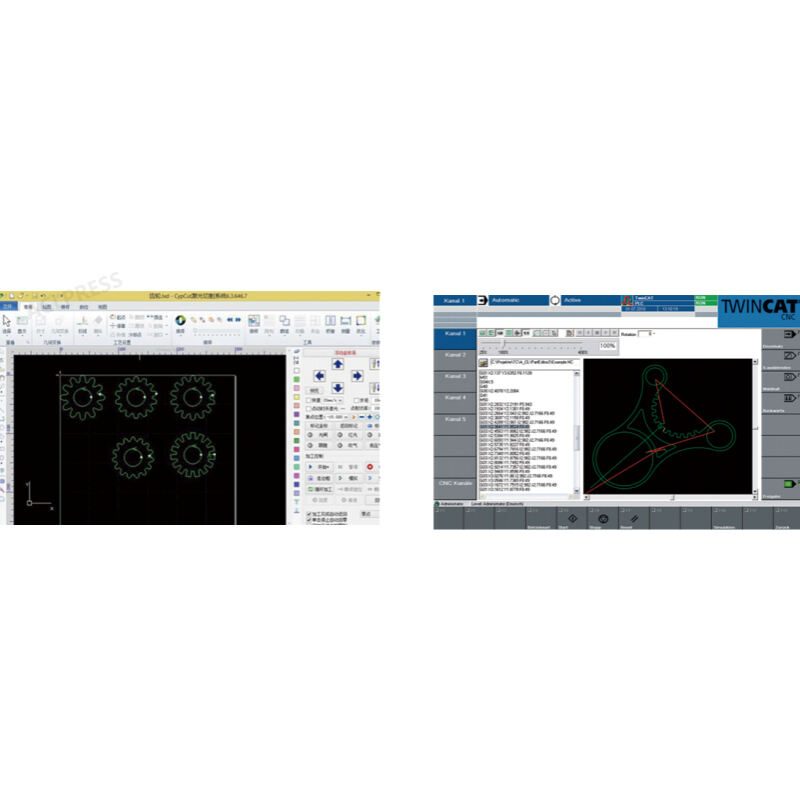

Cypcut or Beckhoff Laser Cutting System

CYP-CUT is user-friendly, offering various file editing functions, remote control support, real-time alarm, and protection.

The intelligent visual control system makes it easier to understand the operation interface, allowing for intuitive adjustments to laser power, gas type, and pressure. Additionally, intelligent edge finding enables automatic positioning, making efficient production easy to achieve.

Air Compressor(Optional)

Volatge Regulator(Optional)

Dust Extraction System(Optional)

French Schneider Electric

Japanese SMC Scale Valve

Panasonic Servo Motor

| Model | KCL-3015 | KCL-4015 | KCL-4020 | KCL-6020 | KCL-6025 | KCL-8025 | KCL-10025 | KCL-12025 |

| Cutting Range (mm) | 3000 *1500 | 4000* 1500 | 4000* 2000 | 6000* 2000 | 6000* 2500 | 8000* 2500 | 10000* 2500 | 12000* 2500 |

| Laser Power (w) | 1000W&1500W&2000W&3000W&4000W&6000W&8000W&12000W | |||||||

| Maximum idle speed | 160 m/min | |||||||

| Maximum cutting speed | 35-80 m/min | |||||||

| Positioning Accuracy | 0.03 mm | |||||||

| Reposition Accuracy | 0.02 mm | |||||||

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TR

TR