Electric Press Brake Machine

1. ACLPRESS electric bending machine is a fully electric machine.

2. Independent compensation of axes Y1 and Y2

3. Higher precision from ACLPRESS

4. Easy and friendly for operations

5. Competitive price

- Features

- Details

- Specifications

- Inquiry

- Related Products

An electronically controlled bending machine is operated and controlled by an electrical control system. In contrast to CNC bending machines, the control system of electronically controlled bending machines is simpler, typically consisting of electrical components, control panels, and circuits.

Operators of electronically controlled bending machines typically adjust parameters such as bending angle, workpiece length, and working speed manually by manipulating buttons or switches on the control panel. Advanced models may feature digital displays or position sensors for enhanced control and monitoring accuracy.

Frankly electronic control bending machines have lower functionality and automation levels compared to CNC bending machines. They are best suited for simple bending tasks, particularly those with lower precision requirements or smaller batch production needs.

Synchro Electric CNC Press Brake eB Icon

Icon is a fully electric machine. Using SYNCHRO technology that controls 2 axes during the bending, thus being able to compensate the axes Y1 and Y2 independently.

This electric press brake is integrated with the highest technology coupled with friendly use.

This model is a top machine that guarantees high precision and competitiveness.

CNC CONTROL SYSTEM

CNC BACK GAUGE

Press brakes are provided are equipped with a back gauge constituted by a solid structure to assure the best repetitiveness and high precision in axe positioning.

MACHINES BLOCK

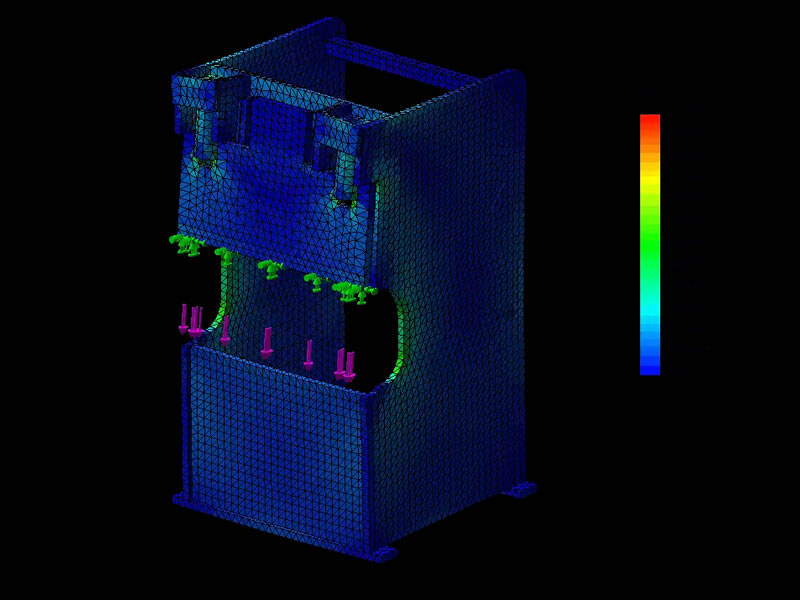

eB Icon series electric press brake features a rigid frame for minimum deflection under the load. ultrasonic controlled & ST‐44 material. Machine welding is made by welding apparatus & welding robots. After the welding, we make a stress relief process by vibration system. After the stress relief process machine frame goes to CNC 5-axis machining centers for accuracy. All reference surfaces and connection holes are machined. By all these processes machine frame sensitivity is protected for a long lifetime.

The Servo Electric Press Brake Provides Energy Saving Up to 50%

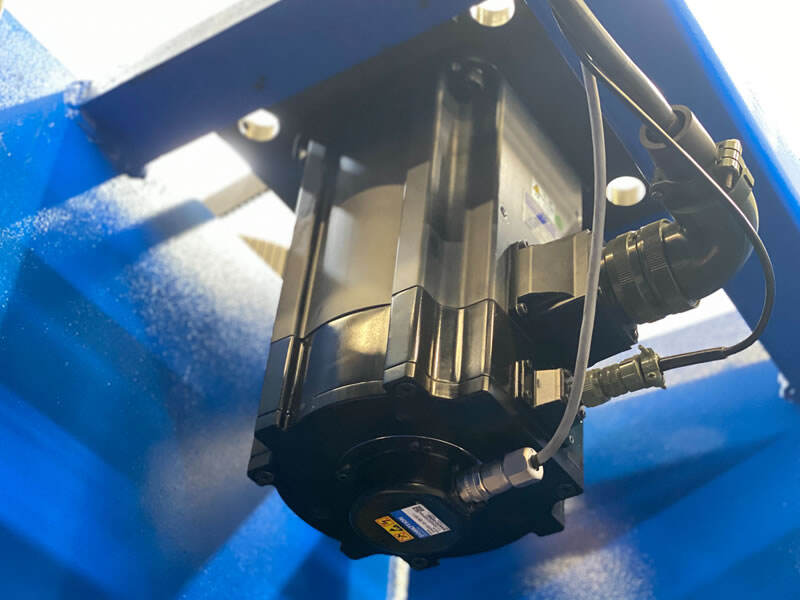

eP series press brake is a compact size, fast, accurate, non-hydraulic bending solution. The ram is driven by a combination of a heavy-duty servo motor and a high-performance ball screw. This innovative machine concept combines productivity, accuracy, flexibility, and reliability with high respect to ecological aspects – we call this concept “ Green Means&rdquo.

SERVO-ELECTRIC TECHNOLOGY

The Servo is a flexible, reliable, and advanced bending machine. Servo Electric Press Brake combines high accuracy, flexibility, and reliability. This concept offers low power consumption, less maintenance, and no hydraulic oil and components for operation.

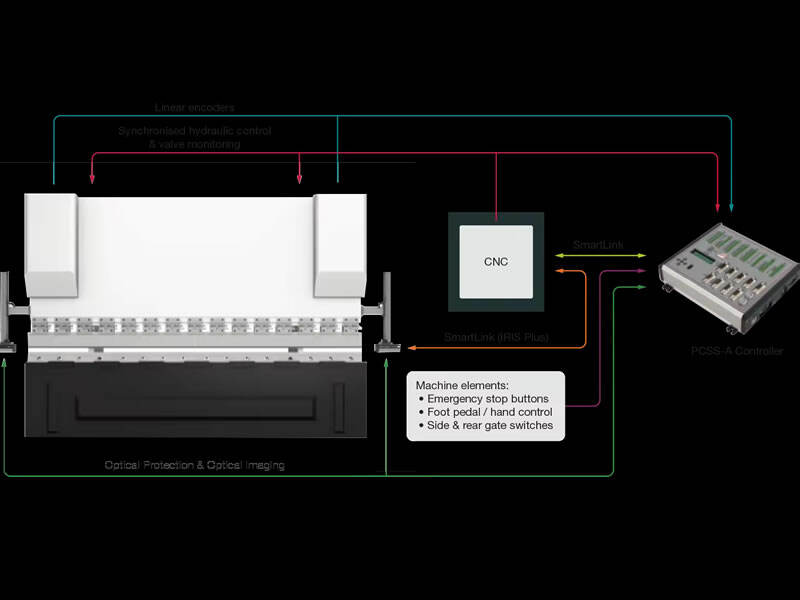

PRESS CONTROL SAFETY SYSTEM

The PCSS-A is a programmable safety controller designed to improve the performance and safety of press brakes. It provides flexibility for the press brake manufacturer and simplifies the design process by combining all related control, safety, and monitoring functions into a single system and eliminates the need for complex integration of third-party components and software. PCSS-A provides an optimum balance of functionality and performance with reduced build cost.

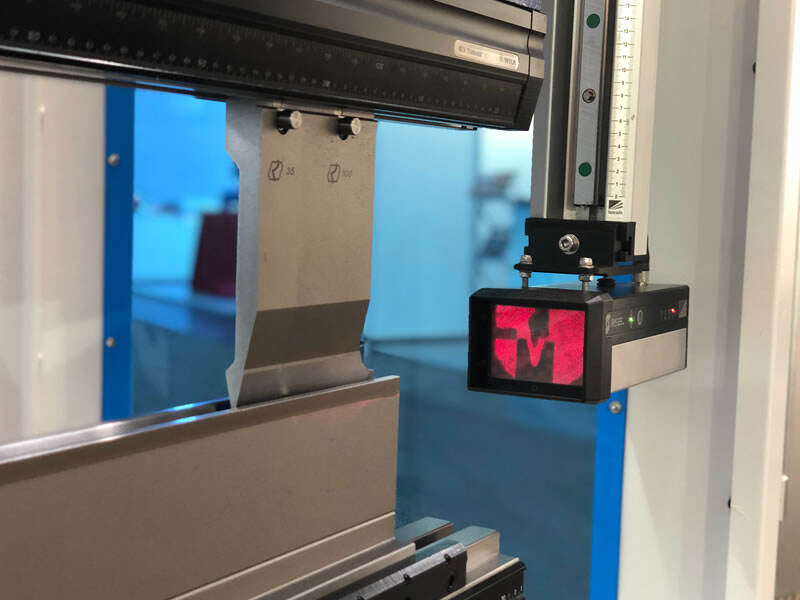

LAZERSAFE OPTICAL SAFETY GUARDS

Performance without compromise. Use LazerSafe LZS-LG-HS guarding system offers a highly effective solution for both operator safety and machine productivity. Designed for use with Lazer Safe's PCSS A Serice, the Lazersafe is category 4 compliant and meets the world’s most demanding international safety standards(CE Certified Category 4 Safety Controller with integrated).

| BGA | X | R | Z1 | Z2 | X2 |

| Stroke(mm) | 750 | 150 | UNDER REQUEST | UNDER REQUEST | 190 |

| Speed(mm/s) | 500 | 170 | 2000 | 2000 | 200 |

| Precision(mm) | +0,02 | +0,05 | +0,05 | +0,05 | +0,02 |

| Type of motor | BRUS HLESS | BRUS HLESS | BRUS HLESS | BRUS HLESS | BRUS HLESS |

| Mechanical system | SCREW | SCREW | RACR | RACR | SCREW |

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TR

TR