Rolling Maching

W11 Symmetrical three-roll plate bending machine;

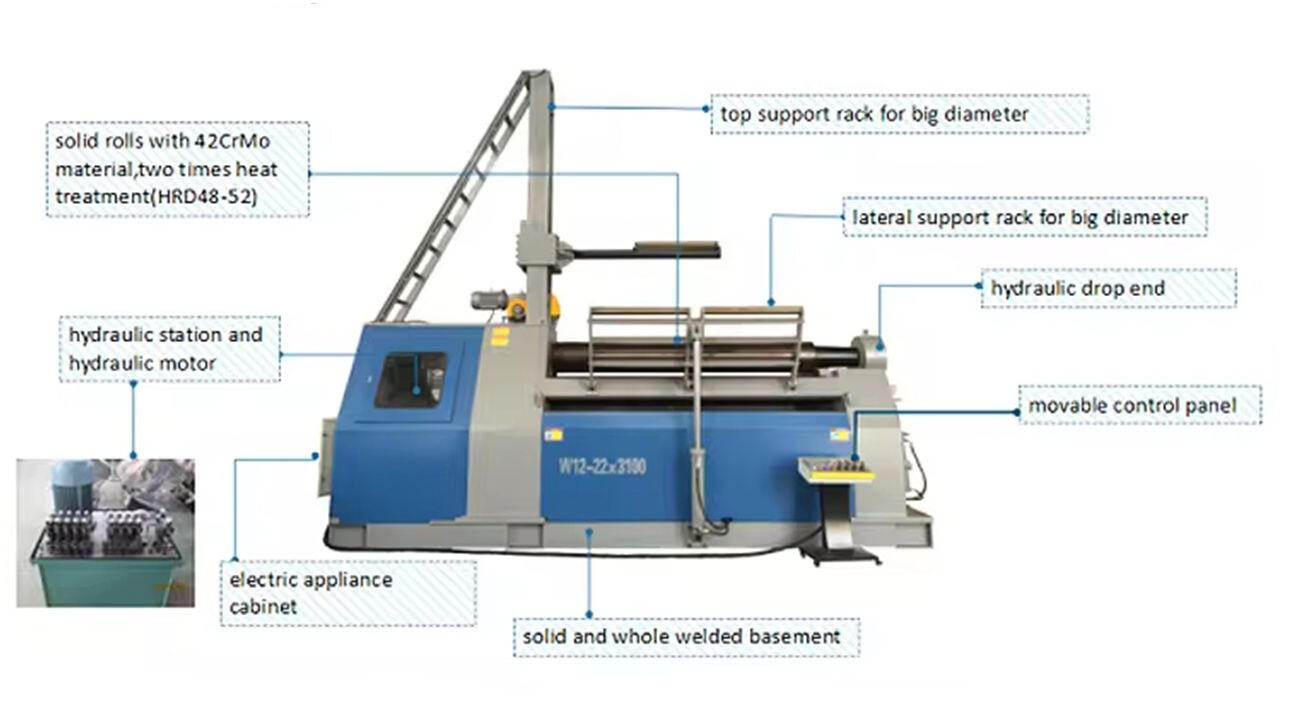

W12H (NC and CNC) full hydraulic arc side-adjusting (numerical display, numerical control) four-roll plate bending machine.

- Features

- Details

- Specifications

- Inquiry

- Related Products

W11 Symmetrical three-roll plate bending machine:

The W11 three-roll plate bending machine features mechanical lifting and transmission. The upper roller can be electrically lifted and lowered, and various specialized side wheels can be added based on customer needs to enable functions like bending iron and coiling pipes;

W12H (NC and CNC) full hydraulic arc side-adjusting (numerical display, numerical control) four-roll plate bending machine:

The W12 series four-roll plate rolling machine features mechanical rotation of the upper roller, while the lower roller and side rollers are lifted through hydraulic transmission. Operation is controlled centrally by electricity. This machine can simultaneously pre-bend and roll cylindrical and curved workpieces at both ends of the plate. Additionally, it can perform shaping and leveling of metal plates, directly pre-bending and saving both material and effort.

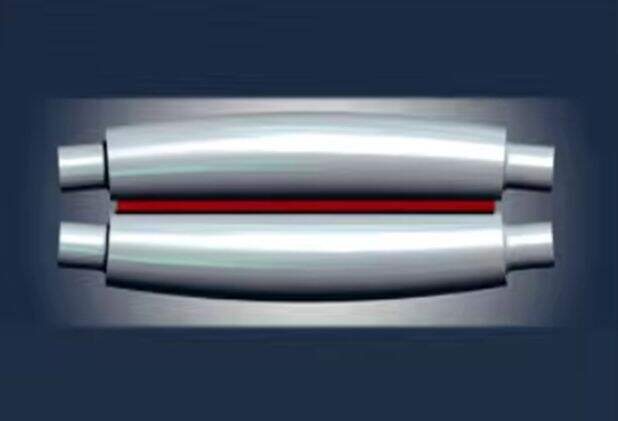

Hardened Rolls

Highly durable carbon steel (C45) rolls are machined by CNC lathes with high precision, without creating a notch effect. The working surfaces of the rolls are induction hardened to HRC 48-52.

Crowning Shape

Rolls are designed as crowning shapes to compensate for the deflections on the rolls during the bending.

Conical Bending Device

With a strong body and angular bottom and side rolls, wide angle and small diameter conical parts are easily bent.

Hydraulic Motor

1-Drive (top roller φ120-430mm) Top roller powered by the planetary reducer, hydraulic motor, and gear system.

2-Drive (top roller φ460-1000mm) Top and bottom roller powered by the planetary reducer, hydraulic motor, and gear system.

Bearing

Rolls are guided with spherical roller bearings and bronze housings. The guiding system requires less lubrication and keeps its precision in the long term.

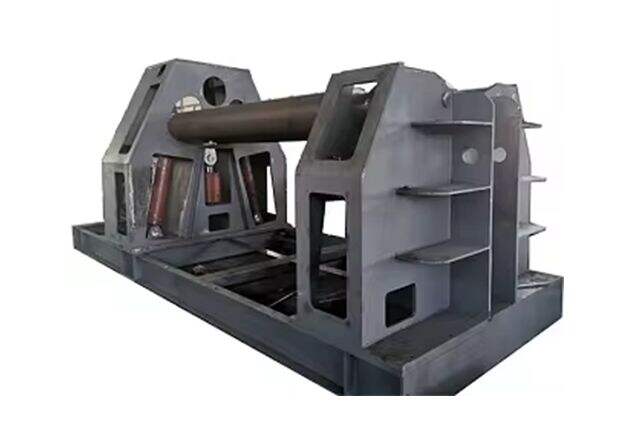

Machine Body

The Machine body is strengthened and lowered to minimize the twists and deformation. The machine body, frame, and steel bar connections are stress-relieved after the welding operation.

Hydraulic Station

Oil Gauge for Pressure

*Hydraulic pump station uses the well-known brand ChangYuan, China.

*Pressure safety valves are used against peak pressures and overload and provide protection for motors and other components.

*The machine's movements are triggered by a hydraulic component.

Cylinder for Pinch and Lateral Rolls

Encoder for Cylinder

Hydraulic Drop End

The drop end opens and then the top roll tilts up sequentially to remove the finished part easily.

Limited Switch for Drop End

The limit switch controls the machine's limit position with a very good protective effect.

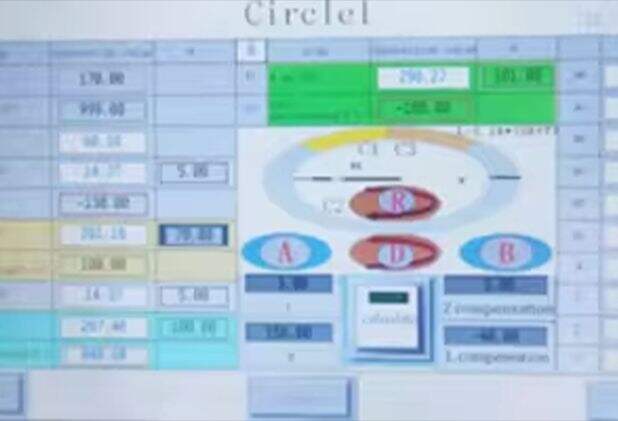

Standard Siemens Control Panel

Human-machine interface, intelligent operation, self-compensating, single operate, high efficiency, safe and convenient.

PLC (Siemens)

A PLC control system ensures the machine's bottom and lateral rolls operate synchronously. Up to 10 steps can be programmed with the touch screen.

Overload Relay

Siemens Contactor

Siemens Power Module

Ground and Polished Rolls for Special Job

Chromate or Polyurethane Treatment

Top support rack for big diameter

(up to 2.5M diameter suggest to select)

Lateral support rack for big diameter

(up to 3M diameter suggest to select)

CNC Control Panel

New Haiwell touch screen with XINJIE PLC can be remotely controlled, makeing operation easier.

CNC System display

The new system can add the graphic library to roll arcs, ellipses, circular rectangles, square rectangles, etc.

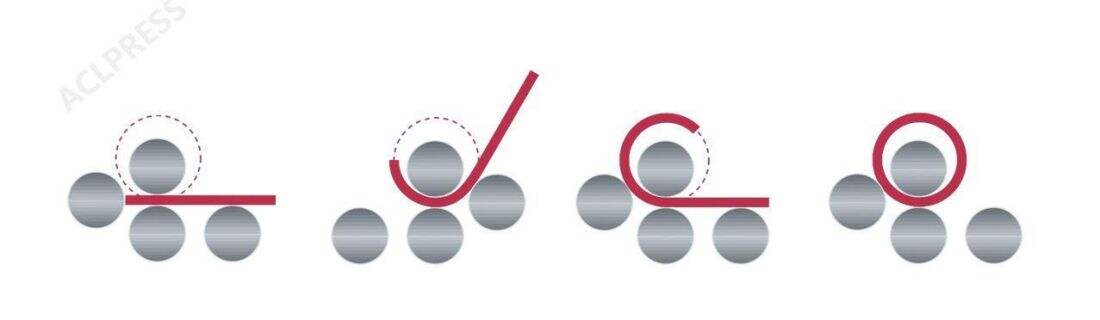

The side roller features a lengthy section designed to "roll up" the pressure plate and securely wrap it around the roller to minimize rebound. In contrast, the curved section of the linear guide rail is shorter, allowing it to form a cylinder with a smaller diameter (including a cone) that can achieve up to 1.1 times the diameter of the upper roller. Consequently, the side roller planetary swing technology offers a 30% reduction in minimum rolling diameter compared to the linear guide rail.

| Standard Equipment Parts | |

| Hardened and solid rolls | Hydraulic motor |

| Digital read out for both sides rollers | Hydraulic drop end |

| Machine body is steel construction | All rolls mount bearing |

| Cone bending device | Standard control panel |

| Hydraulic station | |

| Optional Equipment Parts | ||||

| Ground and polished rolls for special job | ||||

| Hydraulic lateral support rack for large diameter | ||||

| Top support rack for big diameter | ||||

| CNC control panel | ||||

| Feeding table |

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TR

TR