Punching Machine

1. Adopting a starting friction clutch and brake results in smooth operation, reduced ear, and an extended service life.

2. The appliances are PLC-controlled and feature settings for inching single operation, and continuous operation.

3. The slider is fitted with a collapsible safety mechanism and overloading is offset by the safety device to safeguard the entire machine from damage.

4. It offers universality, high accuracy, reliable performance, and ease of operation.

5. With an automatic feeding device, automated stamping operations can be performed.

- Features

- Details

- Specifications

- Inquiry

- Related Products

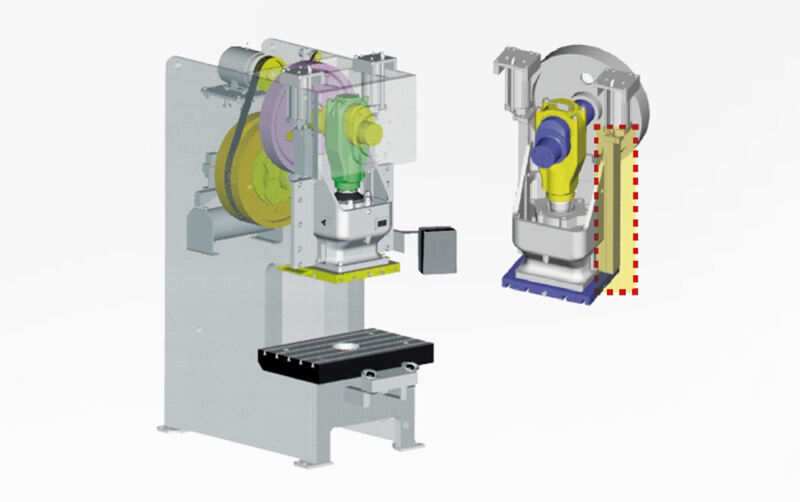

A power press is a type of machine tool utilized for punching, cutting, and shaping metal or other materials. It typically comprises a large housing moving punch and dies that collaborate to create a specific shape or hole in the material. Power presses can be hydraulic, with hydraulic presses offering increased force and precision. They are widely employed in metal fabrication and various industrial applications. ACLPRESS is a prominent brand in the punching machine market due to its expertise and high-quality standards. The company manufactures mechanical presses, pneumatic presses, CNC turret punch presses, and other power presses utilized in diverse metalworking fabrication sectors.

1. The production efficiency can be increased by 30% or so compared with the common crank punch press

2. High rigidity welded fuselage

3. Dry pneumatic friction clutch

4. Safety double solenoid valve

5. High sensitivity hydraulic overload protection

6. Multifunctional high-affinity electronic control system

7. PLC centralized control, convenient operation

HIGH PRECISION FOR SHEET

METAL PUNCHING AND STAMPING

The press body is milling and boring by the PAMA machine center and all the surfaces and holes will be finished machining in opposition.

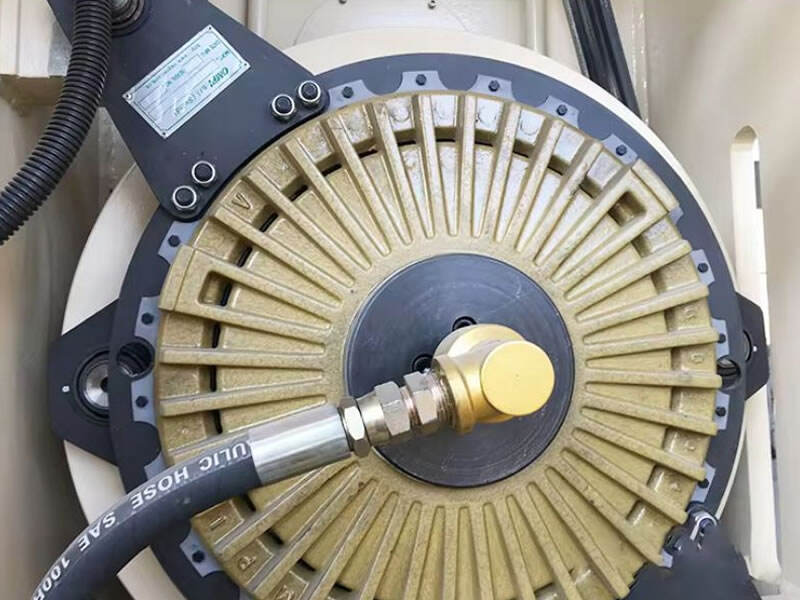

WET TYPE PNEUMATIC

CLUTCH AND BRAKE

Wet-type pneumatic clutch with the imported clutch disc, NOK seals, lower noise and maintenance cost, and longer service life.

Ultra-rigid Body

Structural steel optimization.

The accuracy of stamping products has been greatly improved.

Effectively extend the life of the mold.

| Type | Throat Depth/mm | Motor/kw | Weight/kg | Nominal/kn |

| JH21-25 | 210 | 3 | 2450 | 250 |

| JH21-45 | 225 | 5.5 | 3550 | 450 |

| JH21-60 | 270 | 5.5 | 5150 | 600 |

| JH21-80 | 310 | 7.5 | 6450 | 800 |

| JH21-100 | 330 | 7.5 | 8650 | 1000 |

| JH21-125 | More detalis, please contact our saler, will give you best solution....... | |||

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TR

TR