Shearing Machine

The shearing machine is a device that utilizes the upper and bottom blades to perform a reciprocating straight-line motion to cut sheets in relation to another blade. It operates by utilizing a moving upper blade and a stationary lower blade, with an appropriate blade gap to exert cutting force on plates of varying thicknesses, resulting in the plates being fractured and separated based on the desired dimensions. This machine falls under the category of forging equipment and plays a crucial role in the metalworking sector. Its applications are extensive, serving the aviation, light industry, metallurgy, chemical industry, construction, maritime, automotive, power generation, electrical appliances, interior design, and other sectors by supplying the necessary specialized machinery and complete equipment sets.

- Features

- Details

- Specifications

- Inquiry

- Related Products

A shearing machine is a device used for cutting metal sheets, for a needed size or shape. The operational principle of this machine involves applying force to a metal plate to split it into two parts along a straight line. There are two main types of ACLPRESS shearing machines: mechanical and hydraulic. Mechanical shearing machines use movable and fixed blades cutting metal plates, while hydraulic shearing machines rely on hydraulic pressure to exert force. With the development of automation, shearing machines are now more and more popular in the automotive, construction, and manufacturing sectors for their precise and efficient metal sheet-cutting capabilities. Furthermore, they are also valuable for producing customized parts, shaping metal plates, and achieving clean and precise cuts. Besides, the guillotine cutting knife is also from ACLPRESS to ensure high precision and quality production by various metal plates. The hydraulic swing beam shearing machine is distinguished by its modern design, sturdy heavy-duty construction, and precise cutting abilities. Electric shearing machines provide a cost-effective solution for startups, offering fast cutting speeds and cost efficiency.

1. Fast adjustment for cutting length

2. Optional CNC front feeding table available

3. Optional rear pneumatic sheet supporter

4. Electric angle and gap control for cutting

5. E21S with rear blocking sequence repeat and distance control

6. Durable guillotine knife with four-sides workable cutting edges

Hydraulic Valve Assembly:

Bosch (Rexroth) integrated hydraulic system has a compact structure. It adopts an electro-hydraulic proportional pressure valve, which can control the pressure of the entire process, ensuring stable and reliable performance of the whole machine.

AC Motor:

The rear stopper utilizes an AC motor to drive the ball screw, ensuring a high-level positioning accuracy.

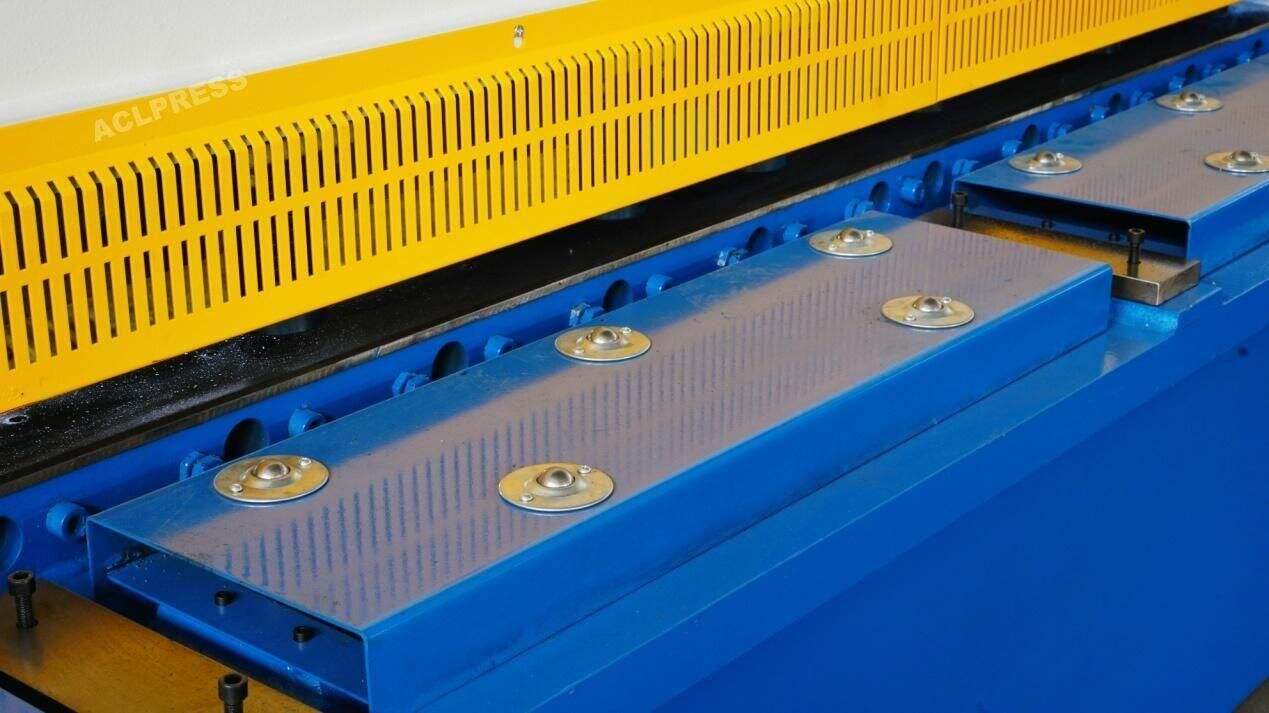

Front Working Table:

Rolling steel balls can reduce frictional resistance and prevent scratching the surface of the workpiece.

Quick blade gap adjustment device

A simple and quick manual adjustment method allows for step-less adjustment of the gap between the blades.

ESTUN E21S

Backgauge control.

Control ordinary motors or inverters.

Intelligent positioning.

Dual programmable digital output.

Workpiece count.

40 program storage, each program has 25 steps.

Unilateral positioning.

Yield function.

One-key backup and restore of parameters.

Metric system.

ESTUN E200PS

CAN bus control X-axis servo.

Shear control.

Dual programmable digital output.

40 program storage, each program has 25 steps.

Unilateral positioning.

Built-in cutting time, retreat delay.

One-key backup and restore of parameters.

Full-function online diagnosis, real-time alarm prompt.

Reserve a safe, supporting material interface.

Color LCD HD display.

Metric/English & Chinese-English. .

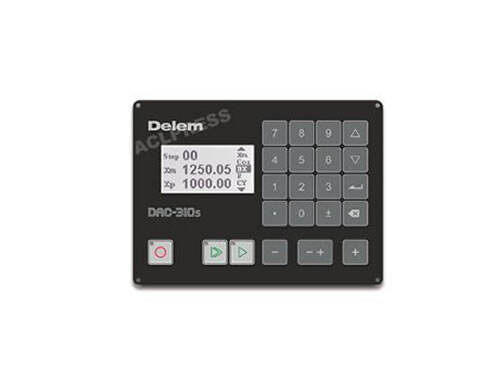

DELEM DAC-310S

Bright LCD 128 x 64 display.

Backgauge control.

Gap control.

Stroke length limitation.

Actual and Programmed position visualization.

Stock counter.

Programmable up to 100 steps.

Panel-based housing.

Servo control / unipolar /

AC two- speed control.

DELEM DAC-360T

Industrial-grade premium touchscreen control.

7" high-resolution colour TFT.

Back / front gauge control.

Cutting angle and gap control.

Manual movement of all axes.

Second and third servo axis (DAC-362T).

USB memory stick interfacing.

Closer photo of ESTUN E21S

| Hydraulic Swing Beam Shearing Machine | QC12Y-8X2500 | QC12Y-8X3200 | QC12Y-8X4000 | QC12Y-8X6000 |

| Cutting Thickness (mm) | 8 | 8 | 8 | 8 |

| Cutting Width (mm) | 2500 | 3200 | 4000 | 6000 |

| Cutting Angle (o) | 1°30′ | 1°30′ | 1°30′ | 1°30′ |

| Backgauge Range (mm) | 20-600 | 20-600 | 20-600 | 20-800 |

| Stroke Number (times/min) | ≥11 | ≥8 | ≥7 | ≥5 |

| Main Motor (kw) | 11 | 11 | 11 | 18.5 |

| Weight (kg) | 5500 | 7200 | 8800 | 18000 |

| Overall Dimensions(LxWxH in mm) | 3180X1700X1700 | 3880X1830X1720 | 4680X1900X1750 | 6880X2260X2350 |

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TR

TR