비틀린 샤프트 벤딩 머신

비틀린 샤프트 벤딩 머신은 비틀린 샤프트 동기화 기술을 사용하여 컴퓨터 프로그램을 통해 벤딩 도구의 비틀림 움직임을 조절하여 자동 벤딩을 수행합니다. 전통적인 하이드라울릭 벤딩 머신과 비교했을 때, 비틀린 샤프트 벤딩 머신은 다음과 같은 주목할 만한 이점이 있습니다:

1. 높은 벤딩 정확도: 비틀린 샤프트 벤딩 머신은 금속 부품의 고정밀도 벤딩을 달성할 수 있습니다. 그 정확한 위치 제어와 강력한 기계 구조는 벤딩의 균일성을 보장하고 각도의 정확도를 유지합니다.

2. 높은 생산 효율: 비틀린 샤프트 벤딩 머신은 빠르고 안정적이며, 많은 양의 벤딩 가공 작업을 효율적으로 완료하여 생산 효율성을 향상시킵니다.

3. 낮은 인건비: 비틀린 샤프트 벤딩 머신은 컴퓨터 프로그램으로 제어되어 수작업 개입을 줄이고, 인건비를 절감하며, 생산 안전성도 향상시킵니다.

- 특징

- 세부사항

- 제품 사양

- 문의

- 관련 상품

트위스티드 샤프트 벤딩 머신은 금속 시트를 원하는 모양으로 구부리고 성형하기 위한 기계 장치입니다. 이는 복잡하고 정확한 모양의 금속 시트를 생산하기 위해 금속 가공 산업에서 널리 사용됩니다. 이 기계는 수평 하부 다이와 수직 상부 다이가 있는 침대로 구성되어 있으며, 이들은 금속 시트에 힘을 가하기 위해 유압 압력에 의해 함께 움직입니다. 기계는 유압 제어 시스템에 의해 작동되며 금속 시트의 다양한 모양, 길이 및 두께에 맞게 조정할 수 있습니다. 프레스 브레이크 머신은 금속 가공을 더 쉽고 효율적으로 만들었으며 현대 제조업에서 필수적인 도구입니다. ACLPRESS는 여러 해 동안 중국에서 최고 등급의 CNC 프레스 브레이크 제조업체 중 하나였습니다. 우리는 다양한 유압 벤딩 머신 옵션을 제공합니다. 천재형은 일반적으로 2D 프로그램 기능과 4축 또는 6축 백가이지 시스템을 갖춘 최상위 기계입니다. 컨트롤러의 가장 일반적인 선택은 DA-69T와 DA-66T입니다. 스마트 타입은 DA-58T와 DA-53T 같은 DELEM 컨트롤러가 장착된 제품으로, 2축 또는 1축 백가이지 시스템을 갖추고 있습니다. 경제형은 스타트업을 위한 경제적인 선택인 비틀림 바 NC 프레스 브레이크 머신입니다. ACLPRESS는 전 세계 고객들에게 적합한 브레이크 프레스 머신을 제조하는 전문 공장입니다. ACLPRESS 엔지니어는 최종 사용자의 작업에 맞춰 다양한 유형의 프레스 브레이크 도구를 설계할 수 있습니다. 우리는 다양한 프레스 브레이크를 판매 중이며 즉시 견적을 받으려면 연락하시기 바랍니다.

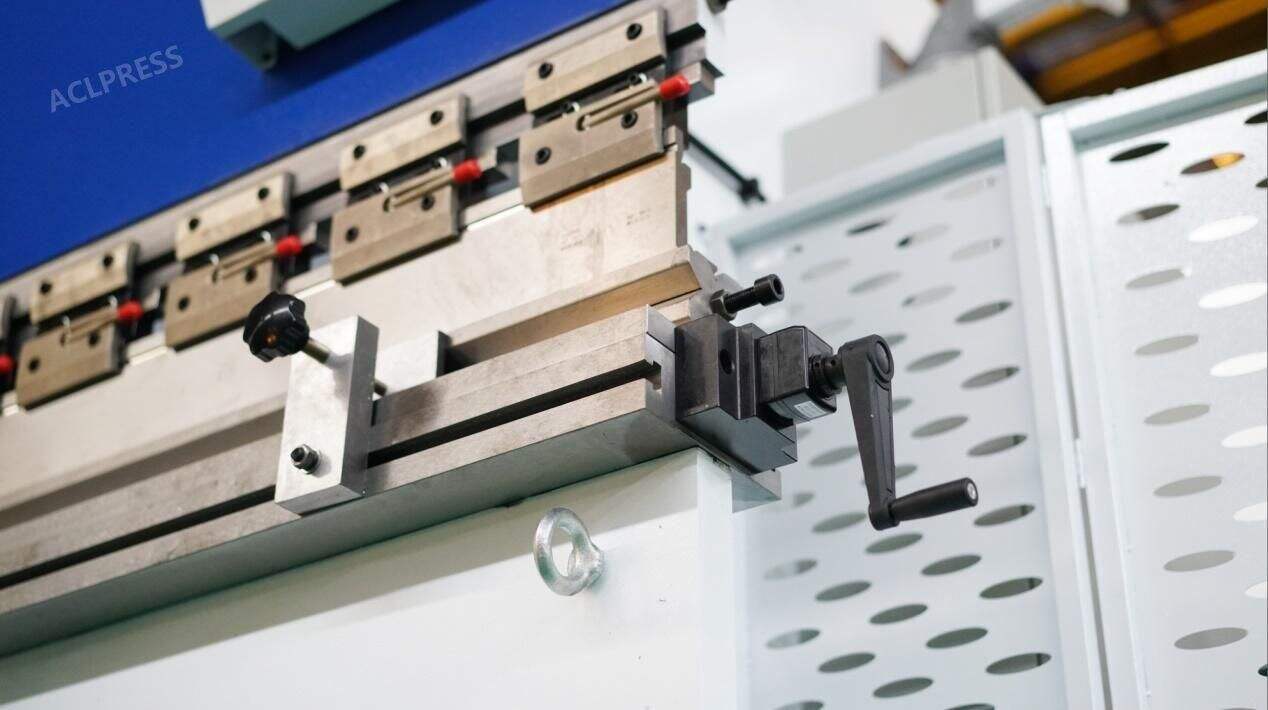

후방 차단용 조정 손가락.

다단 기어 설계는 포지셔닝 범위를 확대합니다.

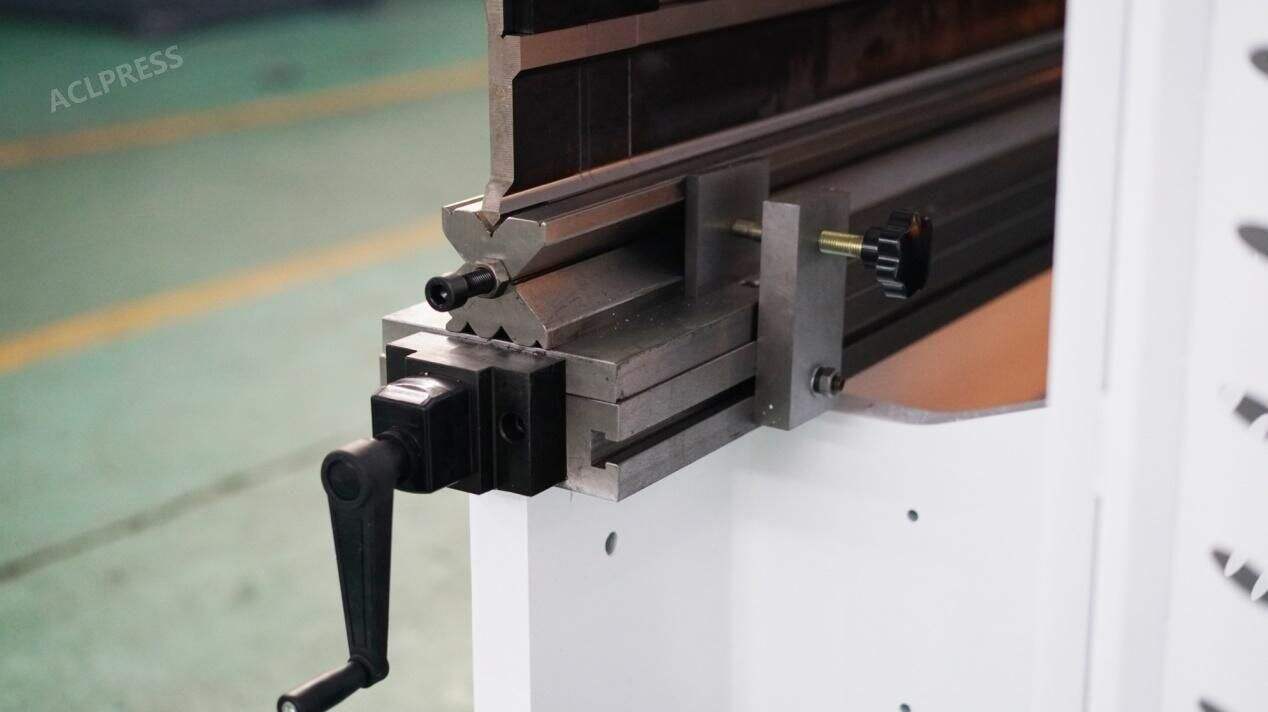

プレ스브레이크 도구

표준 상부 및 다수의 V형 하부 금형은 다양한 두께의 판재를 구부리기에 사용할 수 있습니다. 실제 사용에 따라 더 많은 벤딩 머신 금형을 설계할 수 있습니다.

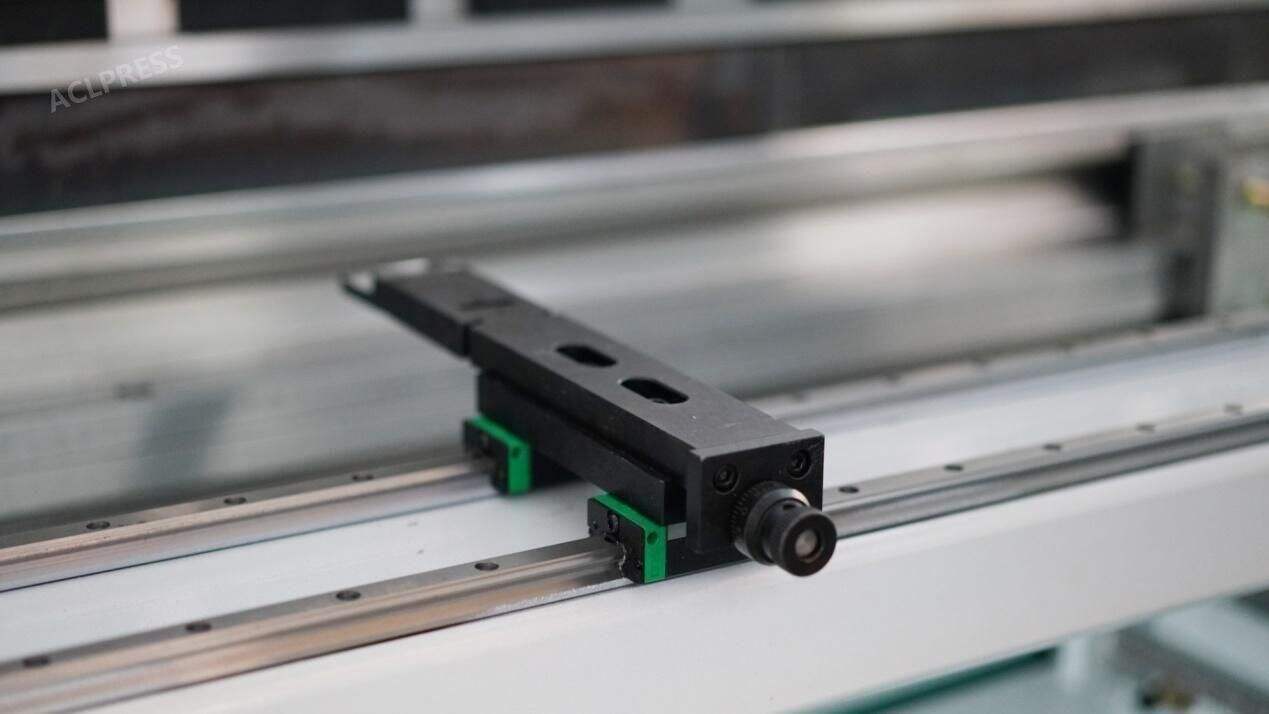

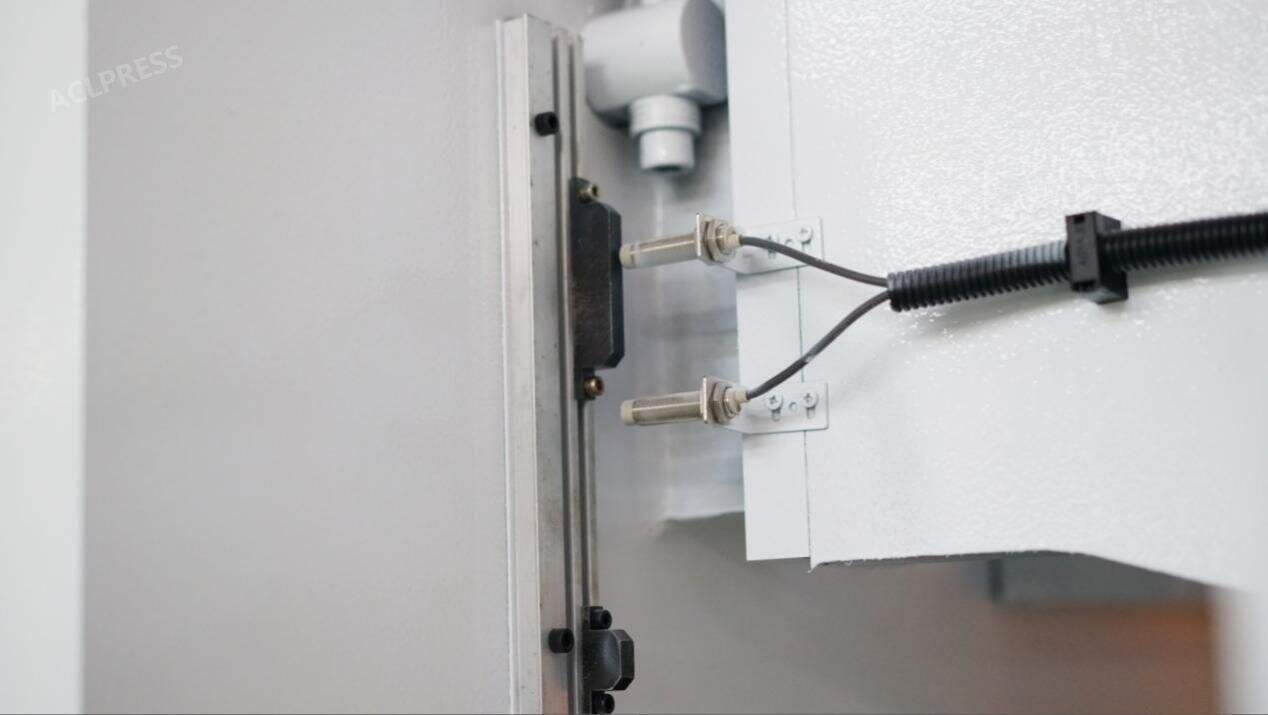

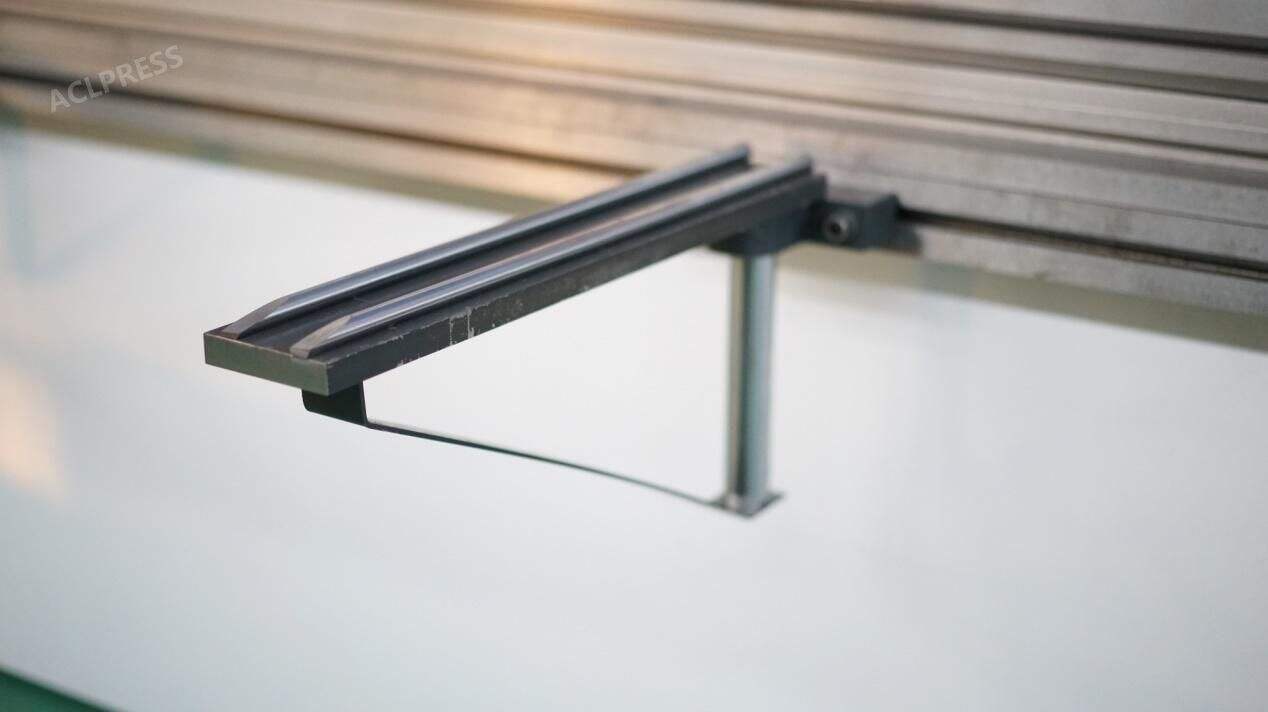

후방 차단

ACLPRESS는 정확한 샤프트 이동을 보장하기 위해 고품질 볼 스크류를 사용합니다. 후방 스톱 손가락과 하강 동작은 스텝 모터로 제어되는 카테pillar 휠 메커니즘을 사용하여 수동으로 조정할 수 있습니다.

ESTUN E21

후방 차단 포지셔닝 제어.

스마트 포지셔닝 제어.

일방향 및 양방향 포지셔닝 기능은 스크류 간의 백래시를 효과적으로 제거합니다.

리트랙션 기능.

자동 참조 검색.

원버튼 파라미터 백업 및 복원.

빠른 위치 색인.

멀티 스텝 프로그램을 위한 40개 이상의 저장 공간이 있으며, 각 프로그램은 25단계로 구성됩니다.

전원 차단 보호.

ESTUN E300P

최신 버전의 터치스크린 수치 제어 시스템.

현재, 시스템의 프로그래밍 시간이 더 짧아졌습니다.

각도 프로그래밍 가능.

터치 스크린 작동.

X축 및 Y축 설정 가능.

자동 양보, 통합 오일 펌프 제어.

DA41T(DELEM)

초고해상도 7인치 와이드 스크린 TFT LCD.

업그레이드된 PCT 강화 유리 터치 스크린.

작업 편의성을 위한 인체공학적 설계.

높은 강도와 긁힘 방지, 장갑 착용 시에도 작동 가능.

패널 설치 기반의 쉘 디자인으로 USB 인터페이스가 있으며, 벤딩 머신의 현재 디자인 스타일과 완벽하게 결합됩니다.

TP10S

10인치 고해상도 컬러 디스플레이 터치스크린.

메뉴식 프로그래밍 인터페이스.

안정적이고 정확한 서보 모터.

CANopen 버스 제어 방식으로 간섭 및 위치 오류를 제거합니다.

각도 프로그래밍을 지원하며, 시스템이 자동으로 구부림 깊이를 계산합니다.

슬라이더 위치 제어가 가능하며, 후방 차단 위치 제어가 가능합니다.

홀딩 시간 설정이 가능합니다.

다중 프로그래밍 작업, 20개의 프로그램, 각 프로그램당 20단계.

소프트 포지션 리밋 기능.

전원-off 메모리

CybTouch 8

아이콘 인식 기능이 있는 8인치 컬러 LCD 터치 스크린.

"EasyBend" 페이지에서 간단한 단일 구부림 작업.

효율적인 구부림 프로그래밍은 대규모 생산 가공의 요구를 완전히 충족시킬 수 있습니다.

구부림 데이터를 자동으로 계산하며, 구부림 각도와 주압을 포함하여 상부 프레스 브레이크 도구의 휨 보상 및 깊이를 계산합니다.

후방 차단각을 자동으로 교정합니다.

| 기계 공구 유형 | 명칭 압력 (KN) |

굽힘 길이 (mm) |

열 간격 (mm) |

목구멍 깊이 (mm) |

실린더 스토크 (mm) |

최대 개방 높이 (mm) |

주 모터 전력 (kW) |

치수 (가로*세로*높이)mm |

| 50T\/1600 | 500 | 1600 | 1300 | 320 | 150 | 430 | 5. 5 | 3000*1400*2300 |

| 70T\/2500 | 700 | 2500 | 2000 | 350 | 150 | 430 | 5. 5 | 3000*1400*2400 |

| 110T\/2500 | 1100 | 2500 | 2000 | 450 | 200 | 500 | 7. 5 | 3000*1600*2700 |

| 110T\/3200 | 1100 | 3200 | 2700 | 450 | 200 | 500 | 7. 5 | 4000*1600*2700 |

| 110T\/4100 | 1100 | 4100 | 3600 | 450 | 200 | 500 | 7. 5 | 4800*1600*2700 |

| 130T/3200 | 1300 | 3200 | 2700 | 450 | 200 | 500 | 11 | 4000*1600*2700 |

| 130T/4100 | 1300 | 4100 | 3600 | 450 | 200 | 500 | 11 | 4800*1600*2700 |

| 170T/3200 | 1700 | 3200 | 2700 | 450 | 200 | 500 | 11 | 4000*1650*2800 |

| 170T/4100 | 1700 | 4100 | 3600 | 450 | 200 | 500 | 11 | 4800*1650*2800 |

| 170T/6000 | 1700 | 6000 | 5300 | 450 | 200 | 500 | 15 | 6600*1750*2900 |

| 200톤/3200 | 2000 | 3200 | 2700 | 450 | 200 | 480 | 15 | 4000*1750*2900 |

| 200톤/4000 | 2000 | 4000 | 3500 | 450 | 200 | 480 | 15 | 4800*1750*2900 |

| 200톤/6000 | 2000 | 6000 | 5300 | 450 | 200 | 480 | 18. 5 | 6600*1850*3050 |

| 250T/3200 | 2500 | 3200 | 2700 | 450 | 250 | 530 | 18. 5 | 4000*1850*3100 |

| 250T/4000 | 2500 | 4000 | 3500 | 450 | 250 | 530 | 18. 5 | 4800*1850*3100 |

| 250T/6000 | 2500 | 6000 | 5300 | 450 | 250 | 530 | 22 | 6600*1950*3200 |

| 300T/3200 | 3000 | 3200 | 2600 | 450 | 250 | 530 | 22 | 4000*1950*3200 |

| 300T/4000 | 3000 | 4000 | 3400 | 450 | 250 | 530 | 22 | 4800*1950*3200 |

| 300T/6000 | 3000 | 6000 | 5200 | 450 | 250 | 530 | 30 | 6600*2150*3400 |

| 400T/4000 | 4000 | 4000 | 3300 | 450 | 300 | 540 | 30 | 4800*2100*3500 |

| 400T/6000 | 4000 | 6000 | 5100 | 450 | 300 | 540 | 37 | 6600*2300*3700 |

| 500T/4000 | 5000 | 4000 | 3300 | 450 | 300 | 540 | 45 | 4800*2100*3600 |

| 500T/6000 | 5000 | 6000 | 5100 | 450 | 300 | 540 | 45 | 6600*2300*3800 |

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TR

TR