Mesin Riveting

Mesin penjepit hidraulik

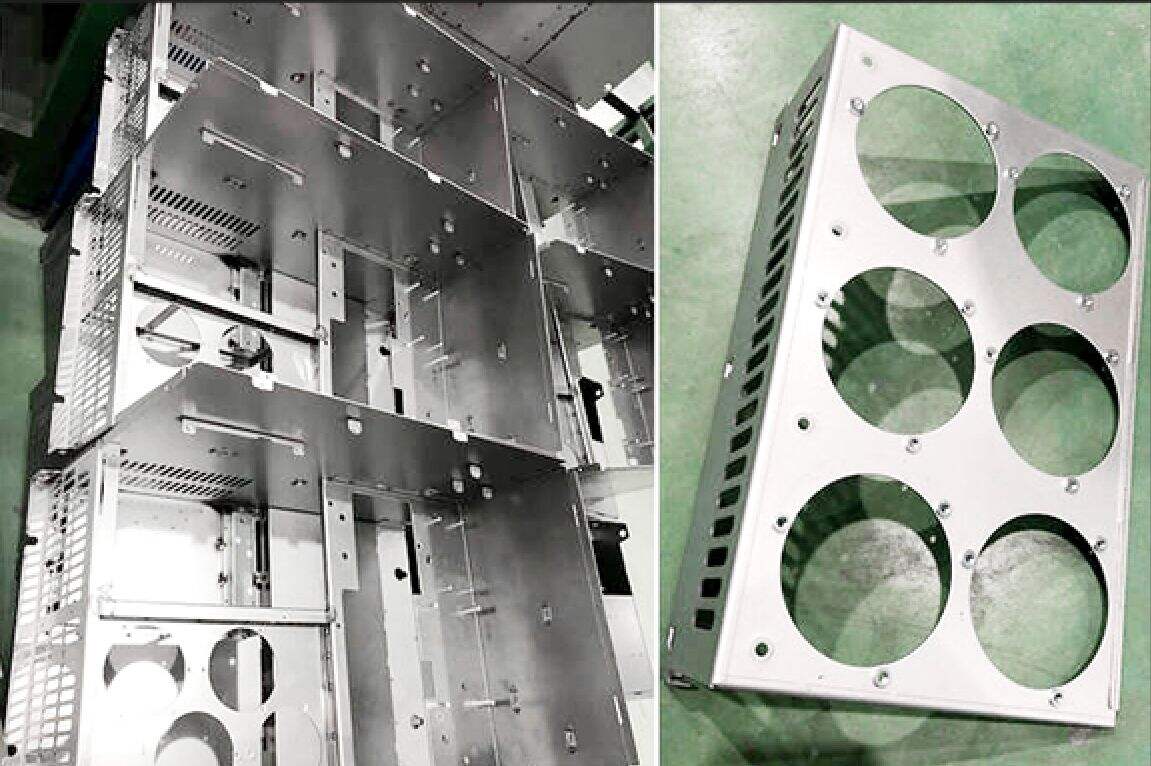

Utamanya digunakan untuk menjepit baut, paku, jepret padat, atau jepret berlubang dalam aplikasi seperti kabinet chasis, spare part mobil, saluran udara, mesin cuci, dan lainnya.

Mesin jepret ACLPRESS didedikasikan untuk meningkatkan efisiensi dan kecepatan operasi Anda. Ini dapat memenuhi berbagai kebutuhan dan cocok untuk semua jenis penjepitan.

- Fitur

- Rincian

- Spesifikasi

- Inquiry

- Produk terkait

Sistem Regulasi Tekanan

Klep overflow yang dipasang digunakan untuk menyesuaikan tekanan secara kontinu untuk mengontrol kebutuhan gaya produk dalam proses pemotongan riveting, memastikan bahwa penyesuaian operasi kualitas pemasangan rivet tekanan setiap pengencang rivet sangat mudah.

Gunakan plat baja sebagai rangka utama

Dibuat melalui pengelasan, diikuti dengan pengolahan panas untuk menghilangkan stres internal dan meningkatkan struktur internal. Selanjutnya, permukaan krusial diperhalus menggunakan peralatan pengolahan besar, memastikan kepatuhan terhadap spesifikasi ukuran dan toleransi geometris. Peralatan yang kuat dan presisi sepenuhnya memenuhi standar kualitas untuk penyelesaian.

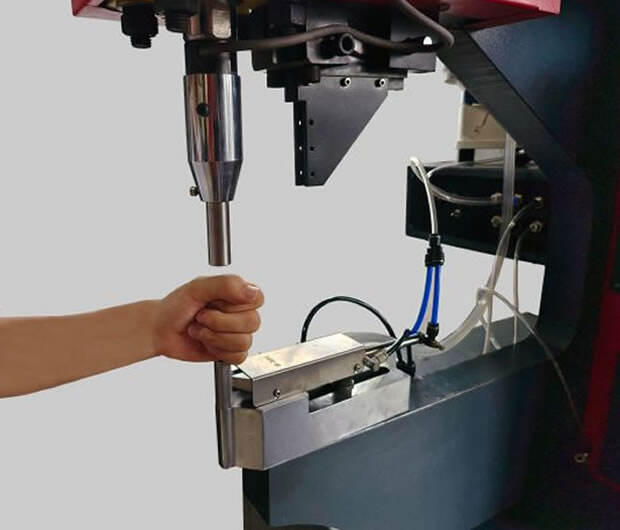

Perangkat tangan anti-tekanan

Perangkat sistem tangan anti-tekanan dilengkapi dengan perlindungan keselamatan yang dapat membedakan antara logam dan non-logam, sehingga meminimalkan cedera operator yang disebabkan oleh kesalahan operasi.

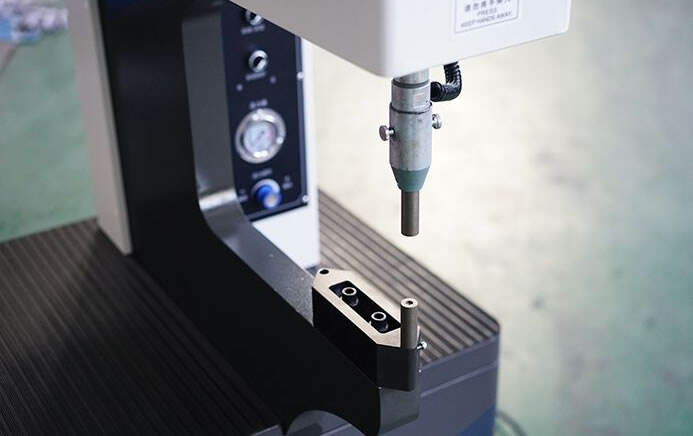

Sistem operasi model atas dan bawah

Sistem panduan sabuk mold atas mencegah mold atas berputar. Kecepatan jatuh mold atas adalah 65mm/s, dan posisinya dapat disesuaikan sesuai kebutuhan. Mold bawah dilengkapi dengan mold standar.

Fungsional, sangat aman, sangat tahan lama, sangat praktis

Untuk pemrosesan dan seleksi, model dibagi menjadi tiga opsi tonase: ekonomis 6 ton, serba guna 8 ton, dan berat 10 ton. Seluruh seri dapat disesuaikan dan mendukung penyelesaian tanpa paku.

Jangkauan penyelesaian tekanan

Saat memproses berbagai produk, cetakan masing-masing perlu diganti. Cetakan Nut S, sekrup FH, dan cetakan stud BSO merupakan bagian dari seri lengkap cetakan yang didistribusikan secara acak.

Struktur mesin penyelesaian

Terdiri dari badan tempat tidur, motor hidrolik pompa minyak, katup balik elektromagnetik, katup pengatur tekanan, dan rangkaian kontrol listrik. Saklar kaki mengontrol sistem hidrolik menggunakan kontrol listrik dan semi-otomatis untuk mentransfer daya. Ini bekerja bersama dengan komponen seperti mekanik + PLC atau pengontrol sirkuit terpadu. Dengan mengganti cetakan yang sesuai berdasarkan permintaan produksi, ia menyelesaikan tugas seperti penyelesaian dan fungsi non-penyelesaian.

Sistem Kontrol Positif

Sistem batas positif menyediakan metode penyesuaian yang mudah untuk mempertahankan secara presisi titik berhenti silinder mesin, secara efektif mencegah penyok pada bahan lunak saat memasukkan paku, seperti Aluminium, Serat Kaca, Papan Rangkaian Terimbas, Plastik dan berbagai bahan komposit. Ketebalan produk dapat akurat hingga ±0,05mm.

Sistem Pengumpan Otomatis, Masukkan 2 jenis paku yang berbeda sekaligus. (Opsional)

Pengaktifan cerdas ON dan OFF pengumpan mangkuk untuk menghindari gesekan lama baut dalam keadaan getaran, yang dapat menyebabkan pelapis terkelupas dan aus. Digunakan untuk ukuran sekrup M2-M6, mur, dan standoff pengiriman otomatis. Panjang maksimum mur dan standoff dapat mencapai 30mm. Sistem ini memiliki fungsi pengangkatan residu baut dengan cepat.

Menerapkan tekanan sepanjang stroke

Selama beroperasi, tekanan yang diterapkan bekerja pada setiap titik stroke, sistem keamanan tetap aktif, dan sistem tidak memerlukan penyesuaian ulang oleh operator, menghemat banyak energi dan waktu pergantian alat.

Sistem Perlindungan Tangan Anti-Tekanan (Standar)

Mesin penyisipan baut pintar dilengkapi dengan sistem perlindungan keselamatan paten wajib dan deteksi otomatis fungsi anti-tekan tangan bekerja saat startup.

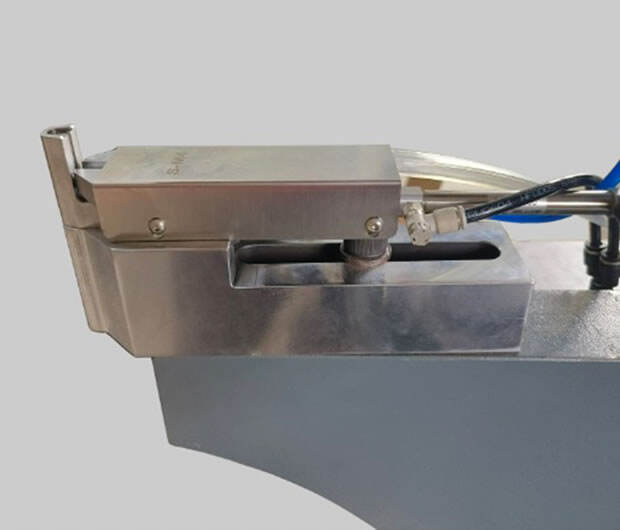

Sistem Pengiriman Otomatis (Opsional)

Penanganan anodizing keras paduan aluminium presisi, tahan aus. Pengoperasian cerdas ON dan OFF pada mangkuk pengumpan untuk menghindari gesekan lama dari komponen pengencang dalam keadaan getaran, yang dapat menyebabkan lapisan terkelupas dan aus. Digunakan untuk ukuran sekrup M2-M6, baut, dan standoff pengiriman otomatis. Panjang maksimal baut dan standoff dapat mencapai 30mm. Sistem ini memiliki fungsi penghilangan sisa komponen pengencang dengan cepat.

Piring Penyokong Basis Mati yang Dapat Diganti

Mesin Pembuatan Botol PET Semi-Otomatis Mesin Pembuatan Botol Mesin Penempaan Botol Mesin Pembuatan Botol PET cocok untuk memproduksi wadah dan botol plastik PET dalam berbagai bentuk.

Utamanya digunakan untuk merivet baut, mur, rivet padat, atau rivet berlubang. Bisa diterapkan pada kabinet rangka, suku cadang mobil, udara, katup udara, casing mesin cuci, dan lainnya.

Sistem kerja model atas dan bawah

Sistem penyesuaian tekanan

| Nama Produk | Mesin Las Riveting | ||

| Kode | M820-NC | M618-NC | M1025-NC |

| Kedalaman Kerongkongan Jenis C | 500mm (19.7") | 450mm (17,7") | 650mm (25,6") |

| Tinggi Kerongkongan Tipe C | 400mm (15,7"") | 400mm (15,7") | 400mm (15,7") |

| Panjang pukulan | 0 hingga 8" (0 hingga 200mm) | 0 hingga 8" (0 hingga 200mm) | 0 hingga 8" (0 hingga 200mm) |

| Kecepatan Tekan Ke Bawah | 100~200mm/detik | 100~200mm/detik | 100~200mm/detik |

| Sistem Pelindung Tangan Saat Menekan | Standar | Standar | Standar |

| Rentang Gaya | 6KN - 78KN | 3KN-57KN | 8KN- 97KN |

| Jangkauan Pengencang | M2 - M12 | M2-M10 | M2-M12 |

| Waktu Diam (menahan tekanan) | Selama 6 detik | Selama 6 detik | Selama 6 detik |

| Stroke Penyesuaian | 3/8"-6"(10-150mm) | 3/8"-6"(10-150mm) | 3/8"-6"(10-150mm) |

| Ketinggian Batas Positif | 100mm | 100mm | 100mm |

| Kemampuan Menjepit | Ketebalan kombinasi 1mm hingga 6mm | Ketebalan kombinasi 1mm hingga 6mm | Ketebalan kombinasi 1mm hingga 6mm |

| Presisi Ulang | +/-1% | +/-1% | +/-1% |

| Sistem pemberian otomatis | Opsional | Opsional | Opsional |

| Sistem Rivet Pra-Keliru Lot | Standar | Standar | Standar |

| Instruksi Pemosisian Laser | Opsional | Opsional | Opsional |

| Tinggi meja kerja | 1050MM(Lingkup Penyesuaian 80MM) | 1050MM(Lingkup Penyesuaian 80MM) | 1050MM(Lingkup Penyesuaian 80MM) |

| Berat kasar | 750kg | 650kg | 1100KG |

| Kapasitas Daya Masukan/Tegangan | 380V Tiga-fase 5 inti 50HZ | 380V Tiga-fasa 5 inti 50-60HZ | 380V Tiga-fasa 5 inti 50-60HZ |

| Dimensi Mesin Tunggal (MM) | 45,7"x37"x81,5" (L1160xW940xH2070mm) |

43,3"x36,6"x78,8" ( L1100*W930*H2000mm) |

47,3"x66,9"x92,5" (L1200xW1700xH2350mm) |

| Sistem Penggerak | PLC drive, dengan layar sentuh TG765G 7" | PLC drive, dengan layar sentuh TG765G 7" | PLC drive, dengan layar sentuh TG765G 7" |

| Daya Motor Pompa Hidrolik | 3 KW | 2.25 KW | 3 KW |

| Tangki minyak | 70L | 60L | 60L |

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TR

TR