Rohrlaserschneidmaschine

Die spezielle Rohrlaser-Schneidmaschine besteht aus 7 Achsen.

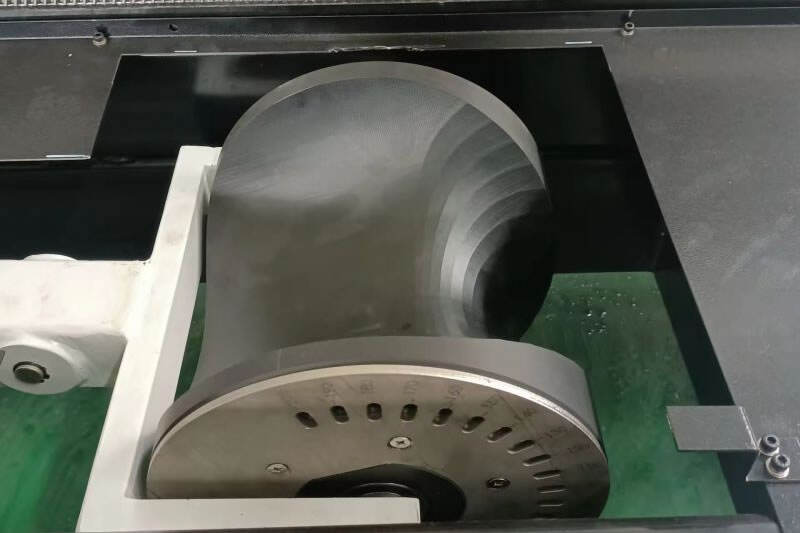

Sie kann verschiedene Arten von Rohren schneiden, wie runde, quadratische, rechteckige und ovale Röhren, mit einer Maschinenlänge zwischen 1 und 11 Metern.

Die Maschine ermöglicht die Einmalformung von 6-Meter-Röhren.

Mit einem Futterwellen- und Zugwellensystem minimiert das Gerät erheblich den Verarbeitungsabfall.

Es kann mehrere Röhren in verschiedenen Richtungen und Durchmessern schneiden sowie Oberflächen in variablen Winkeln ausfräsen.

ACLPRESS ist als Branchenexperte im Rohrenschneiden bekannt.

- Funktionen

- Einzelheiten

- TECHNISCHE DATEN

- Anfrage

- Verwandte Produkte

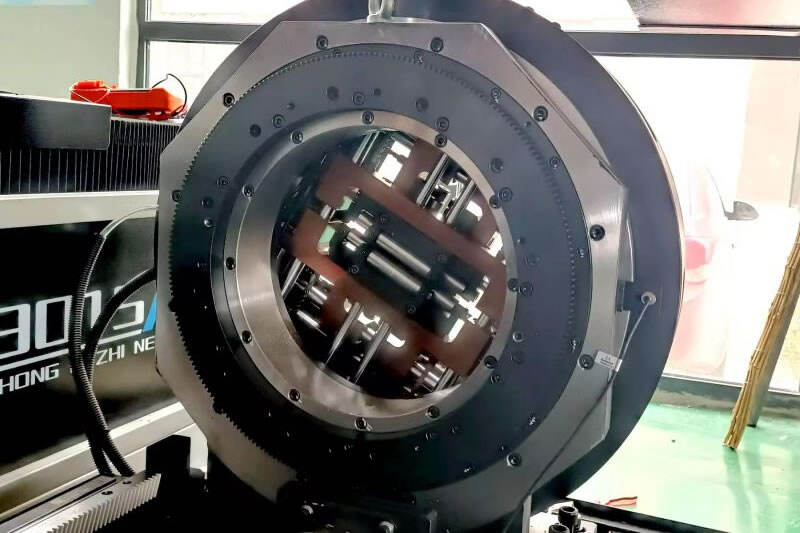

ACLPRESS Laserschneidmaschine hat eine stabile Leistung und hohe Präzision, mit einem Reduktor einer deutschen Marke, um sicherzustellen, dass die Maschine bei hoher Geschwindigkeit startet und stoppt, und ein Doppeltreibenantriebssystem mit Zahnradübertragung, um die Leistung zu gewährleisten. Alle elektrischen Komponenten und Laser sind im Steuerkasten untergebracht, mit einer ausgezeichneten staubdichten Konstruktion, um die Lebensdauer der elektrischen Komponenten zu verlängern. Außen am Steuerkasten ist ein Klimagerät mit automatischer Konstanttemperatur montiert, um Schäden an den Komponenten im Sommer zu verhindern.

Laser-Schneidkopf

Drei Schutzlinsen schützen die Kollimations- und Fokuslinsen effizient. Bidirektionale optische Wasser Kühlung verlängert die kontinuierliche Arbeitszeit erheblich.

Manuelles Fokussieren ist nicht erforderlich, da die Software die Fokuslinse automatisch anpasst, was den Vorgang vereinfacht und zehnmal schneller als manuell ist.

Verschiedene stabile und qualifizierte Marken von Laserköpfen sind für ACL-Laser erhältlich.

Frankreich MOTOREDUCER

Stabiler Betrieb

Niedriges Geräusch

Großes Ausgangsdrehmoment

Hohe Übersetzung

Hanli Brand Industrie Kühlgerät

Hanli Wasserkühler

Automatisches Schmiersystem

Halten Sie die Schienen und Räder während des Betriebs der Maschine für die X-Achse, Y-Achse und Z-Achse geschmiert.

Wartungsfrei bei Hochgeschwindigkeits-Schneiden.

Automatischer Pneumatischer Spannkolben

Die pneumatischen Schraubstockklammern sind dank Ein-Schlüssel-Befestigung und automatischem Zentrieren 3-mal schneller als elektrische Schraubstockklammern. Mit großer und konstanter Klemmkraft werden schwere Röhren stabil gehalten. Es werden zwei Reihen von Rollen verwendet, um einen breiten Klemmbereich und eine hohe Schnittgenauigkeit zu ermöglichen.

Segmentierter Automatischer Träger

Die intelligente Rohrstützungsdesign löst das Problem der Verformung während des Schneidvorgangs bei langen Röhren.

Große Marke Faserlaser

MAX & Raycus & IPG Marke Lasersystem.

Höhere Elektro-Optik-Umsetzungseffizienz, exzellente Zuverlässigkeit, Modularität, einfache Wartung und geringe Reflexionsresistenz.

Es verwendet ein luftgekühltes kompaktes Strukturdesign mit einem Halbleiterfasermedium zur Erzeugung von Laserlicht, welches umweltfreundlich ist. Die mechanische Struktur ist einfach, der Optikweg bleibt konstant, wodurch praktisch keine Wartung erforderlich ist und eine stabile Schneidleistung gewährleistet wird.

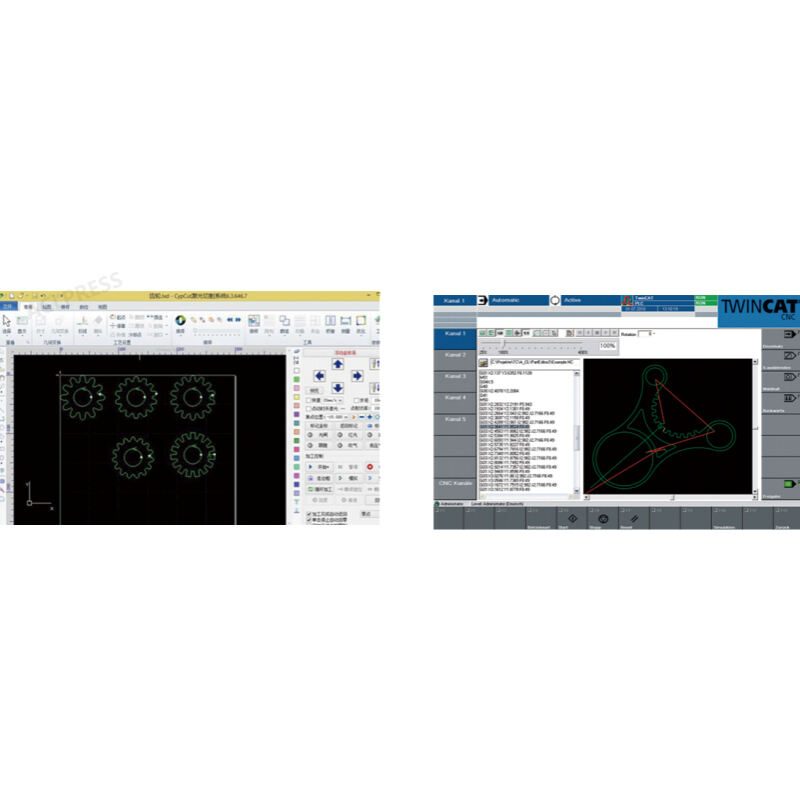

Cypcut oder Beckhoff Laserschneidsystem

CYP-CUT ist benutzerfreundlich und bietet verschiedene Dateibearbeitungsfunktionen, Unterstützung für Fernsteuerung, Echtzeitwarnungen und Schutz.

Das intelligente visuelle Steuersystem erleichtert das Verständnis der Bedienoberfläche und ermöglicht intuitive Anpassungen der Laserleistung, des Gasteils und des Drucks. Darüber hinaus ermöglicht die intelligente Kantenerkennung eine automatische Positionierung, wodurch eine effiziente Produktion leicht zu erreichen ist.

Luftkompressor (optional)

Spannungsregler (optional)

Staubextraktionssystem (optional)

Französisch Schneider Electric

Japanischer SMC Skalventil

Panasonic Servomotor

| Modell | KCG-6022 | KCG-6035 | KCG-9022 | KCG-9035 | KCG-12022 | KCL-12035 |

| Rohrschneid-Länge (mm) | 6000 | 6000 | 9000 | 9000 | 12000 | 12000 |

| Spanndurchmesser (mm) | 220 | 350 | 220 | 350 | 220 | 350 |

| Laserleistung (W) | 1000W-20000W | |||||

| Maximale Positionierbeschleunigung (m/min) | 10 m/s2 | |||||

| Positioniergenauigkeit (mm) | 0.03 mm | |||||

| Wiederholgenauigkeit (mm) | 0,02 mm | |||||

| Drehachsgeschwindigkeit | 80 rpm | |||||

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TR

TR