thiết bị ống gió

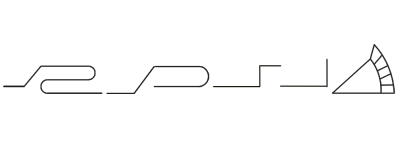

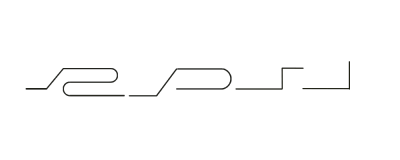

MÁY ỐNG GIÓ

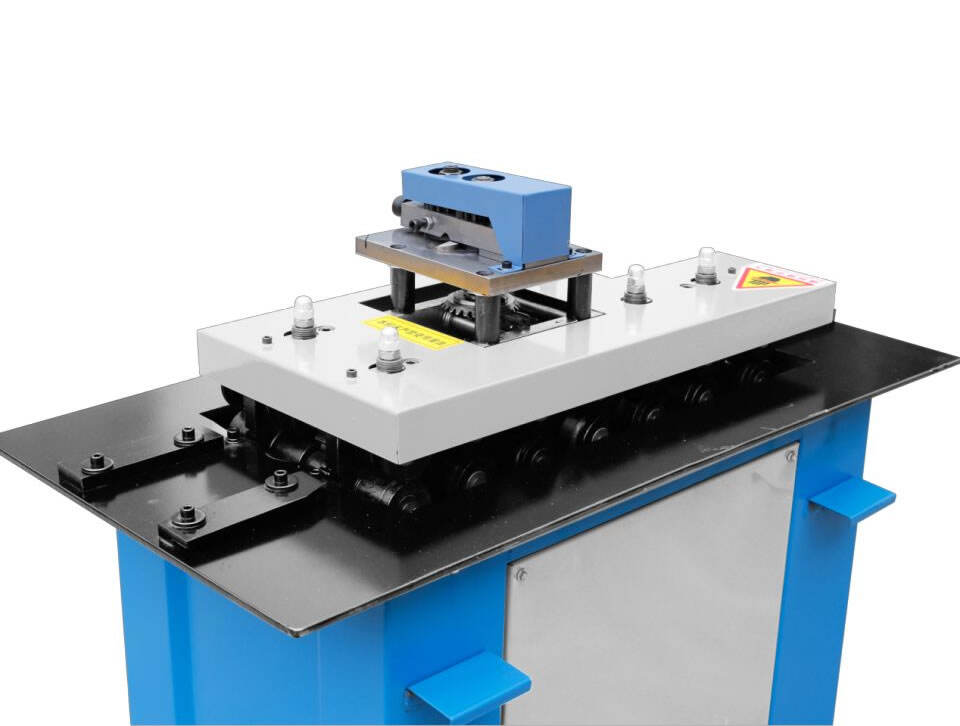

Máy uốn viền là thiết bị không thể thiếu trong ngành sản xuất đường ống dẫn gió. Nó có thể xử lý nhiều loại tấm kim loại để đáp ứng yêu cầu nối tấm. Phiên bản tiêu chuẩn có khả năng xử lý các tấm kẽm dày 0.5-1.5mm. ACLPRESS khuyến nghị sử dụng con lăn cường độ cao làm từ vật liệu GCr15, tăng đáng kể tuổi thọ so với vật liệu thông thường và nâng cao hiệu suất công việc tổng thể.

- Đặc điểm

- Chi tiết

- Thông số kỹ thuật

- Truy vấn

- Sản phẩm liên quan

Các thông số kỹ thuật chính

| Mô hình | Độ dày tấm | Trọng lượng | Kích thước (DxRxC) |

| ACLL-12 | 0.5-1.2 | 220 | 1050x570x1020mm |

| ACLL-15 | 0.8-1.5 | 280 | 1150x600x1100mm |

| ACLE-12 | 0.5-1.2 | 215 | 1050x570x1020mm |

| ACLD-12 | 0.5-1.2 | 200 | 1050x570x870mm |

| ACLA-12 | 0.5-1.2 | 200 | 1050x570x870mm |

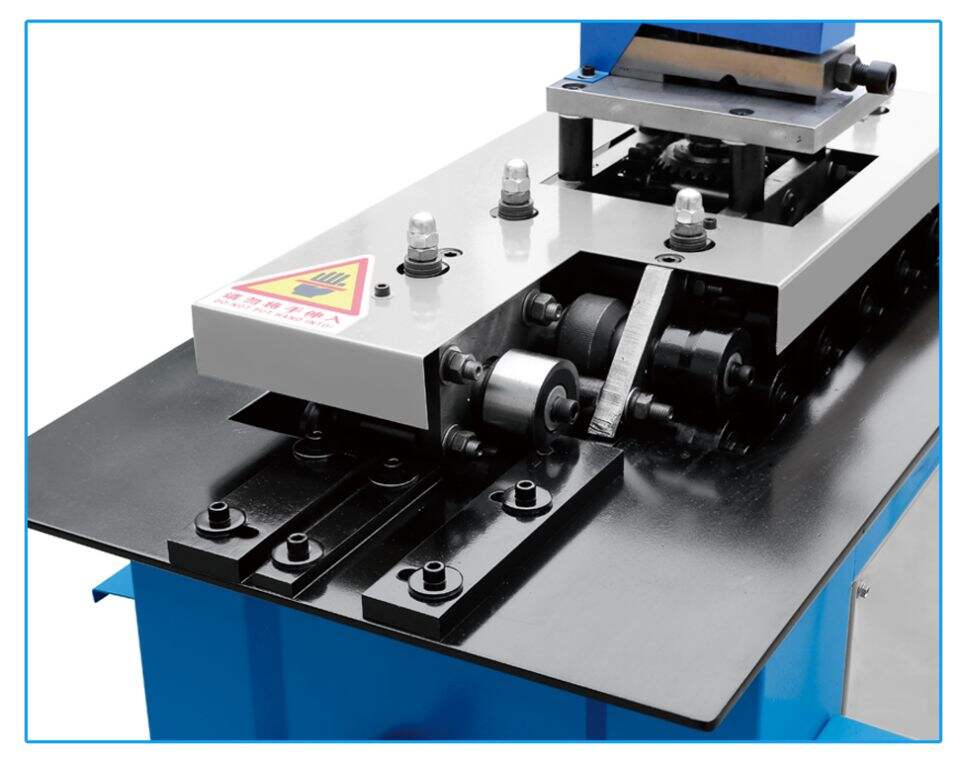

Máy đa chức năng chuẩn hóa

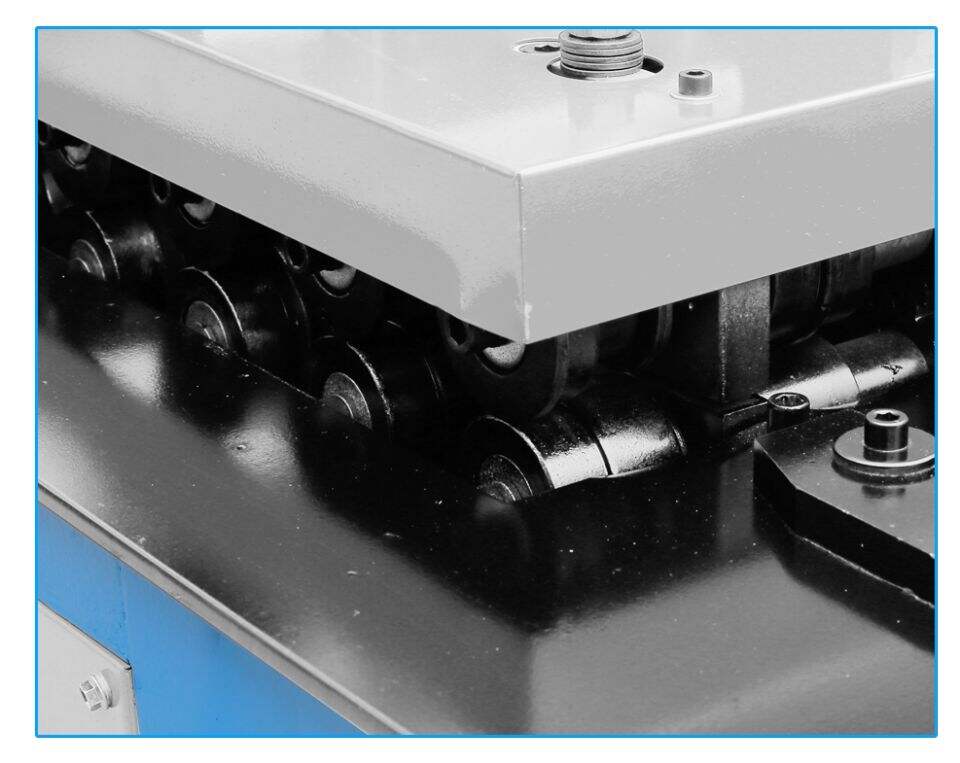

Bánh xe lăn được làm từ thép cacbon 45#, đã qua xử lý nhiệt ngâm dầu, độ cứng đạt 40-60 độ. Tuổi thọ sử dụng là 2-3 năm.

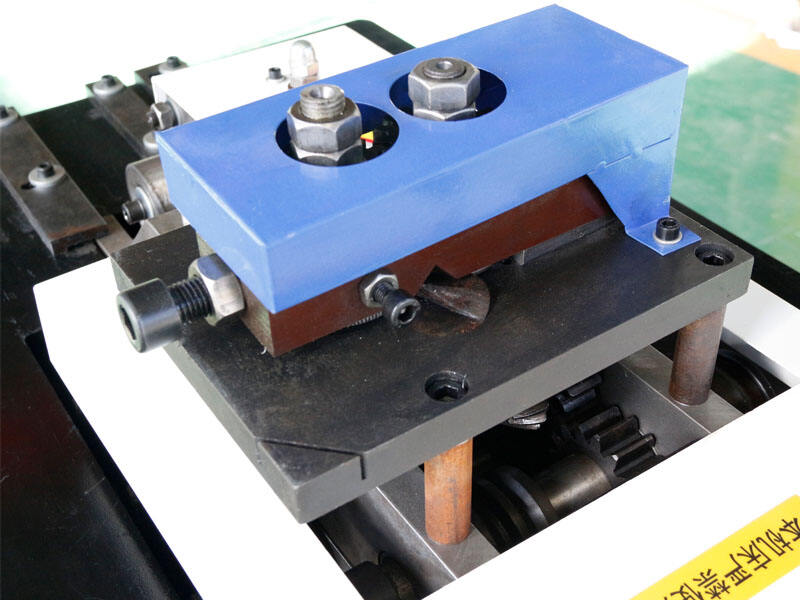

Đầu bạc máy khóa thép

Chất liệu của bánh xe áp lực là thép bi GCR15, được xử lý nhiệt trong môi trường chân không. Sau quá trình xử lý lần thứ hai, sẽ có độ lệch tâm nhỏ, tốt chứ? Độ cứng đạt 55-60 độ và tuổi thọ tăng lên 3-5 năm.

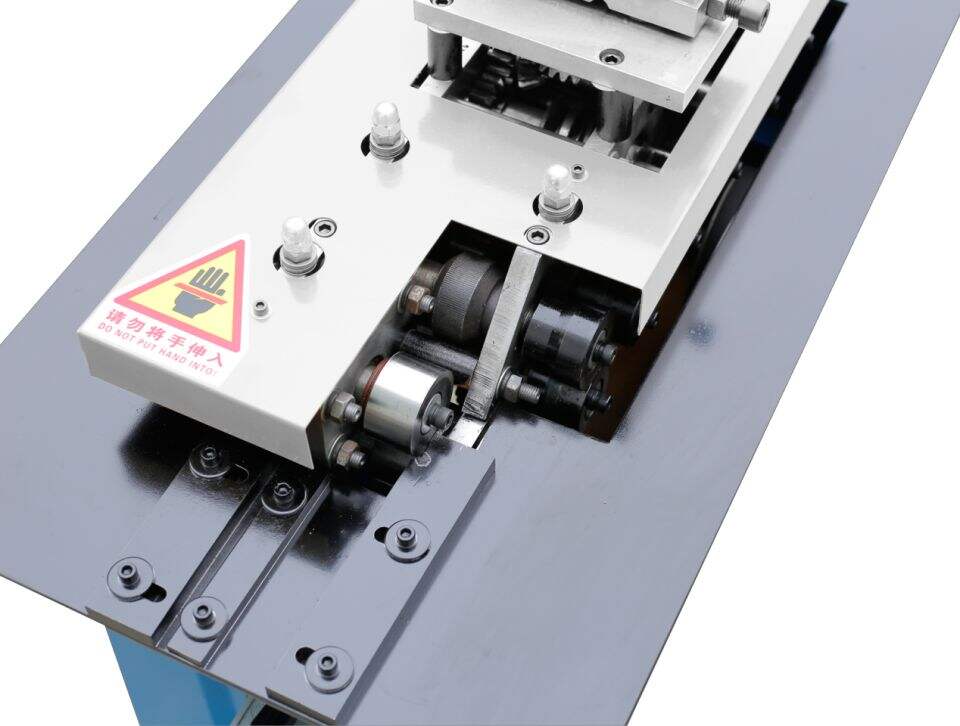

Thanh điều chỉnh

Chất liệu thước dẫn được làm từ thép lò xo chất lượng cao với độ cứng 55-60 độ. Nó bền bỉ sau khi được ngâm dầu và xử lý nhiệt.

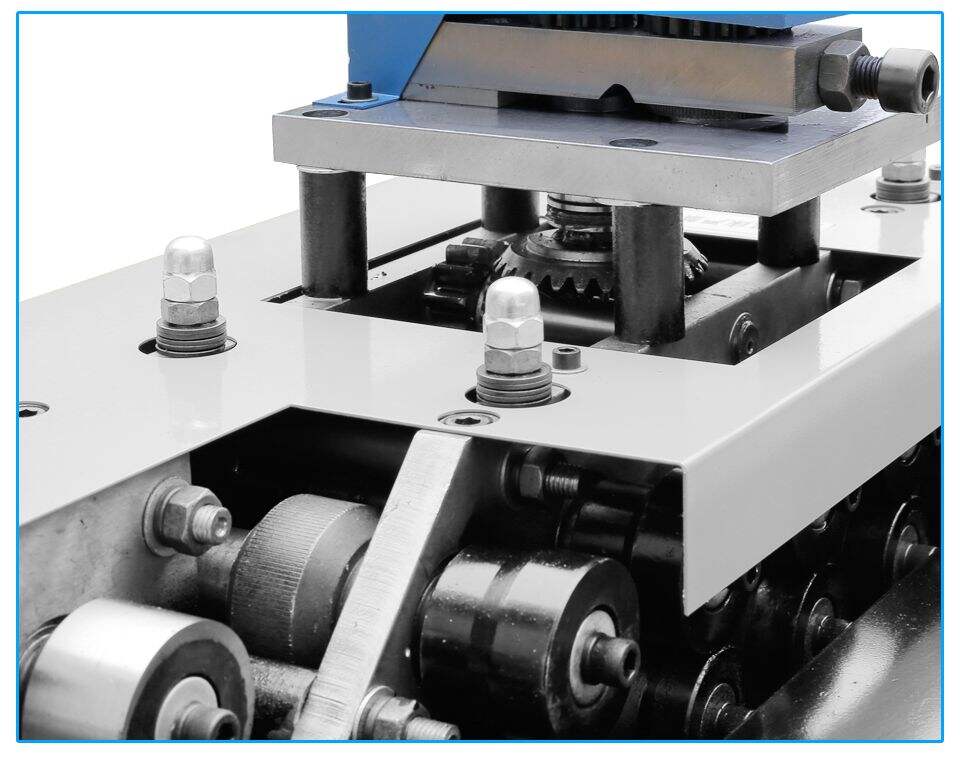

Cổng nạp vào của máy ép

Lỗ nạp của máy ép đa năng ACLPRESS được trang bị các cuộn phẳng có khe hở điều chỉnh được. Các cuộn này làm phẳng tấm trong khi tác động của sự không đều đến độ chính xác của việc tạo cắn.

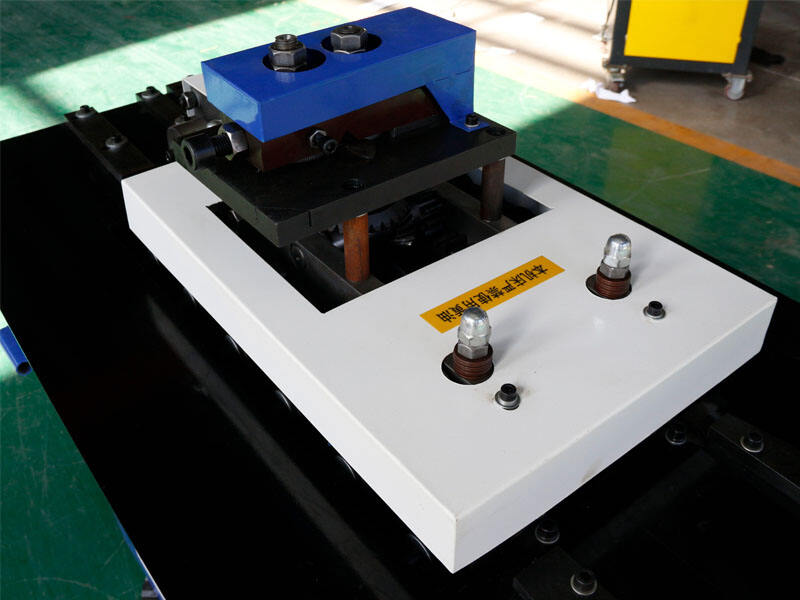

Bảng điều chỉnh đa năng

Công tắc chức năng của máy tạo cắn ACLPRESS có thể được thực hiện bằng cách điều chỉnh vị trí của bảng chức năng với ốc vít, dễ dàng vận hành và hiệu quả cao trong xử lý.

Cuộn máy ép

Các cuộn của máy cắn aclpress được làm từ hợp kim chống mài mòn chất lượng cao, đã qua xử lý nhiệt toàn thân. Chúng có độ cứng phù hợp và khả năng chống mài mòn tốt, cường độ làm việc mệt mỏi liên tục dưới tải trọng cao của các cuộn vượt quá 250 giờ.

Bánh xe đa hướng của máy cắn

Máy cắn ACLPRESS được trang bị bánh xe nặng và chống mài mòn, di chuyển linh hoạt và thích hợp cho nhiều môi trường làm việc phức tạp khác nhau. Nó có thể được di chuyển một cách dễ dàng bằng cách đẩy dọc theo.

| Mô hình | Độ dày tấm mm |

Hình dạng | Sức mạnh kW |

Trọng lượng kg |

Kích thước L*W*H |

| SA-12HB | 0.5-1.2 |  |

1.5 | 220 | 1050x570x1020mm |

| SA-15HB | 0.8-1.5 |  |

2.2 | 280 | 1150x600x1100mm |

| SA-12B | 0.5-1.2 |  |

1.5 | 215 | 1050x570x1020 mm |

| SA-12 | 0.5-1.2 |  |

1.5 | 200 | 1050x570x870 mm |

| SA-12C | 0.5-1.2 |  |

1.5 | 200 | 1050x570x870 mm |

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TR

TR