Mini elektro drukvouwmachine

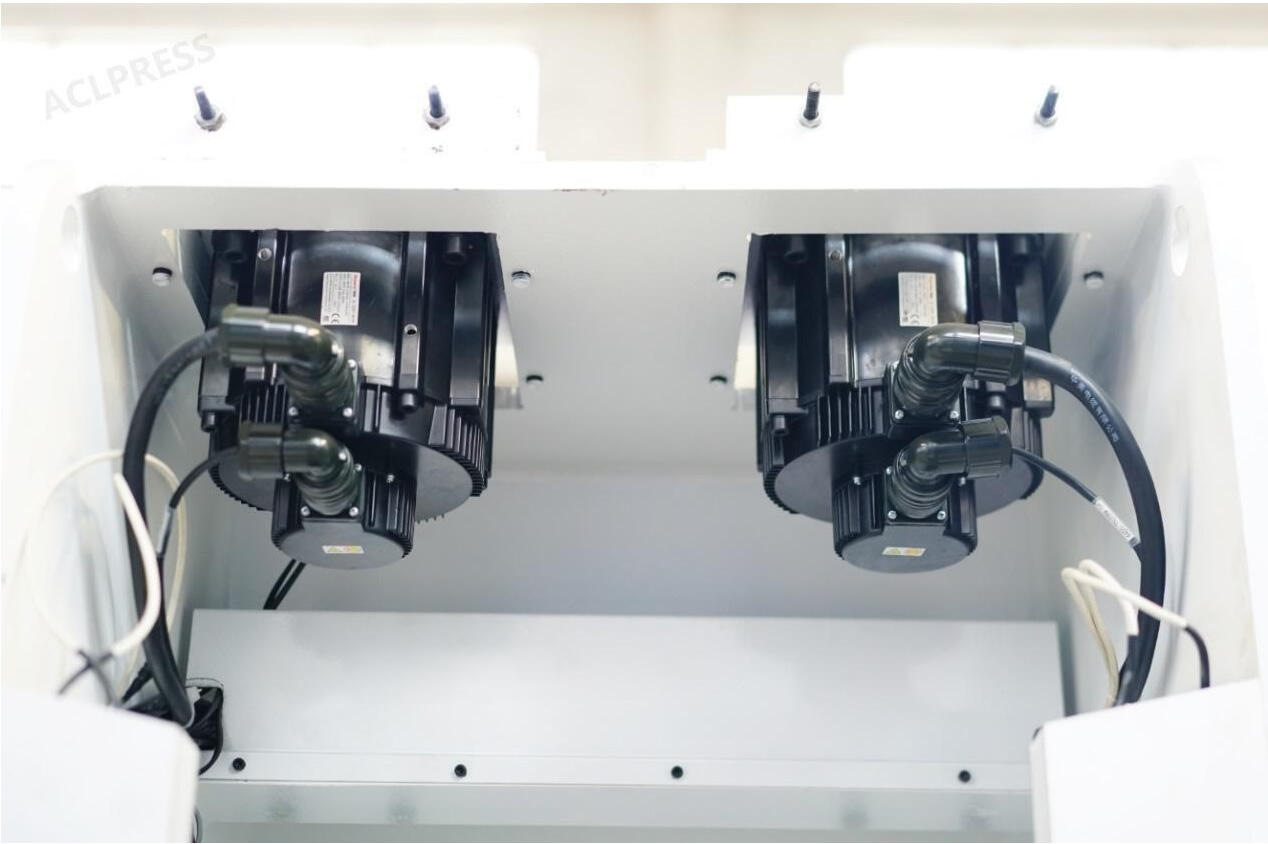

1. Volledig elektrisch systeem en bediening

2. Y1 en Y2 assen

3. Eenvoudig en flexibel in bediening

4. Mini maar stabiele structuur

5. Lagere kosten

- Kenmerken

- Details

- Specificaties

- Navraag

- Gerelateerde producten

De Mini-buigmachine is een compacte buigmachine met verschillende voordelen:

Kleine afmetingen: Minibuigmachines zijn doorgaans klein en nemen minder ruimte in, waardoor ze geschikt zijn voor beperkte werkomgevingen. Ze bieden meer flexibiliteit dan grotere machines en kunnen worden geplaatst in kleinere werkplaatsen of beperkte ruimtes.

Eenvoudige bediening: Minibuigmachines hebben een vereenvoudigd besturingssysteem dat eenvoudig en intuïtief te gebruiken is. Operateurs kunnen snel hun functies begrijpen zonder complexe programmering of CNC-vaardigheden te vereisen.

Vervoerbaarheid: Door hun compacte afmetingen zijn minibuigmachines gemakkelijker te vervoeren dan grotere machines. Deze vervoerbaarheid is handig om te verhuizen tussen werkplekken of ter plaatse verwerking uit te voeren.

Ideaal voor kleine schaal productie: Mini buigmachines zijn goed geschikt voor kleine schaal productie of projecten. Ze bieden efficiënte oplossingen voor eenvoudige buigoperaties in kleine projecten of steekproefproductie.

Kosten-effectief: Mini buigmachines zijn doorgaans betaalbaarder dan grotere modellen, waardoor ze een kosteneffectieve optie zijn voor gebruikers met budgetbeperkingen en de initiële investeringskosten verlagen.

Het is echter belangrijk om te noteren dat mini buigmachines beperkingen hebben. Door hun grootte en vermogensbeperkingen kunnen ze mogelijk niet geschikt zijn voor het verwerken van grotere of dikker werkstukken. Voor taken die hoge precisie en complexe vormen vereisen, kunnen geavanceerdere en grotere buigmachines nodig zijn. Daarom is het essentieel bij het kiezen van een buigmachine de specifieke werkvereisten en de verwachte productievolumes volledig te overwegen.

CNC PRESS BRAKE SMART-FAB B SERIES

Ontwerpinnovaties zijn gebaseerd op jarenlange ervaring en hebben geleid tot de Smart-Fab serie Press Brakes die snellere vouwen mogelijk maken en een betere terugkeer en achterste afmeting bieden. Press Brakes laten u toe om precisieonderdelen in massa-productie te brengen en uw kosten per onderdeel te verlagen.

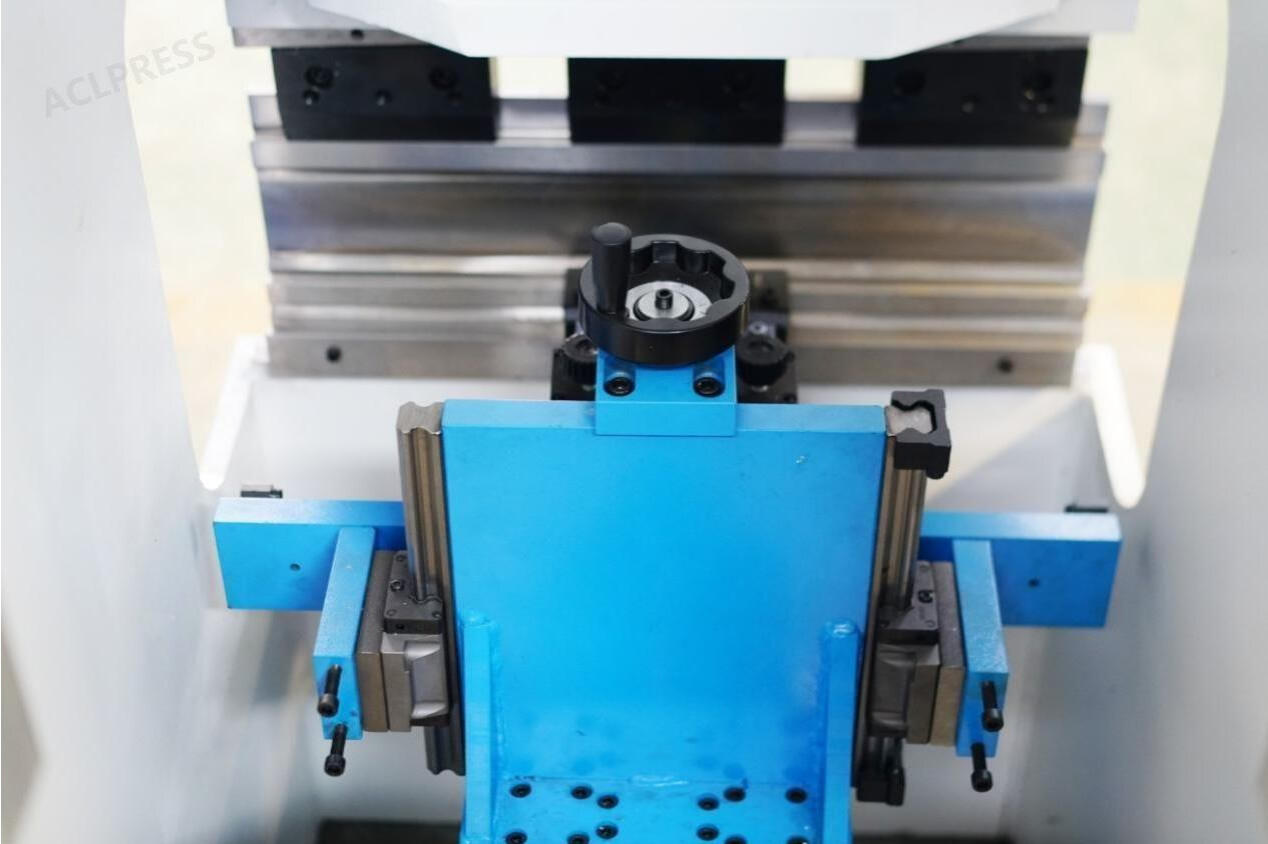

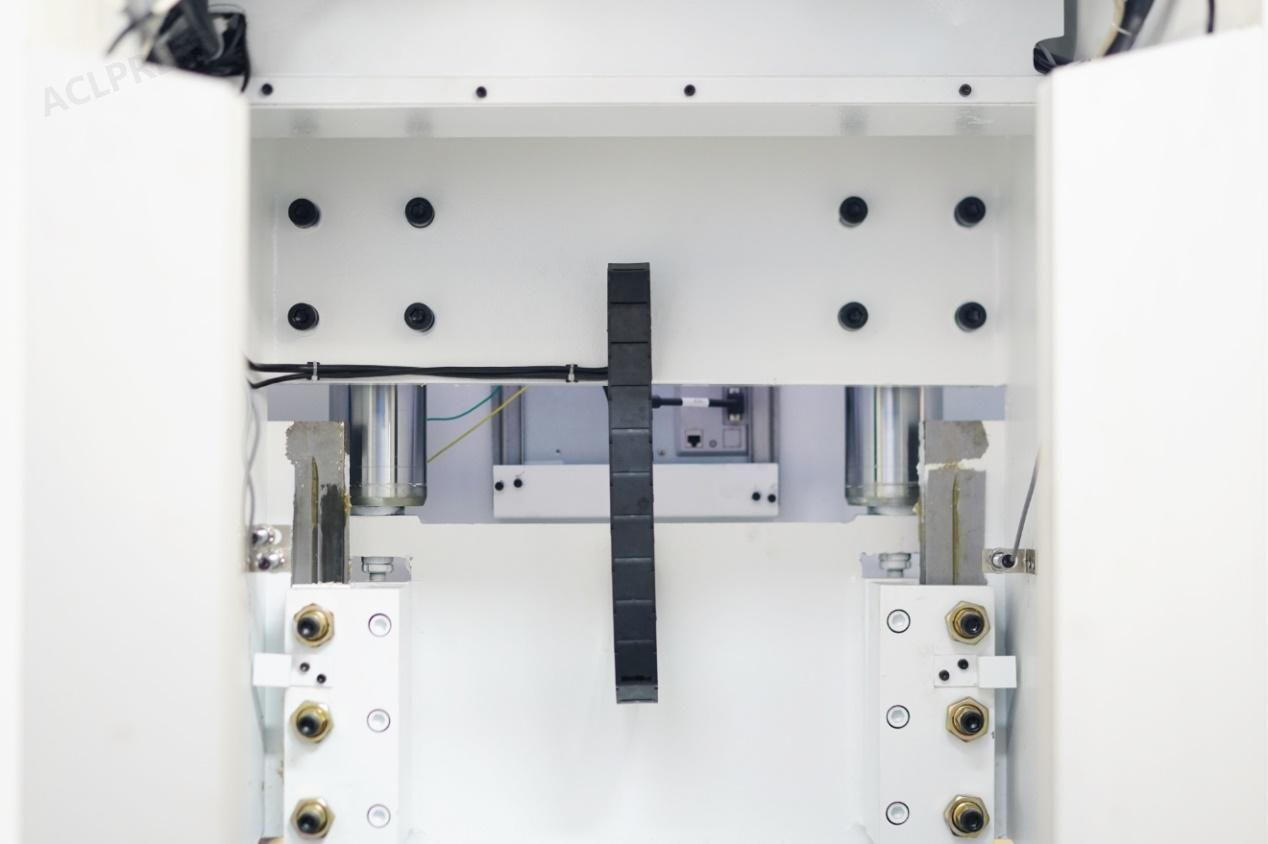

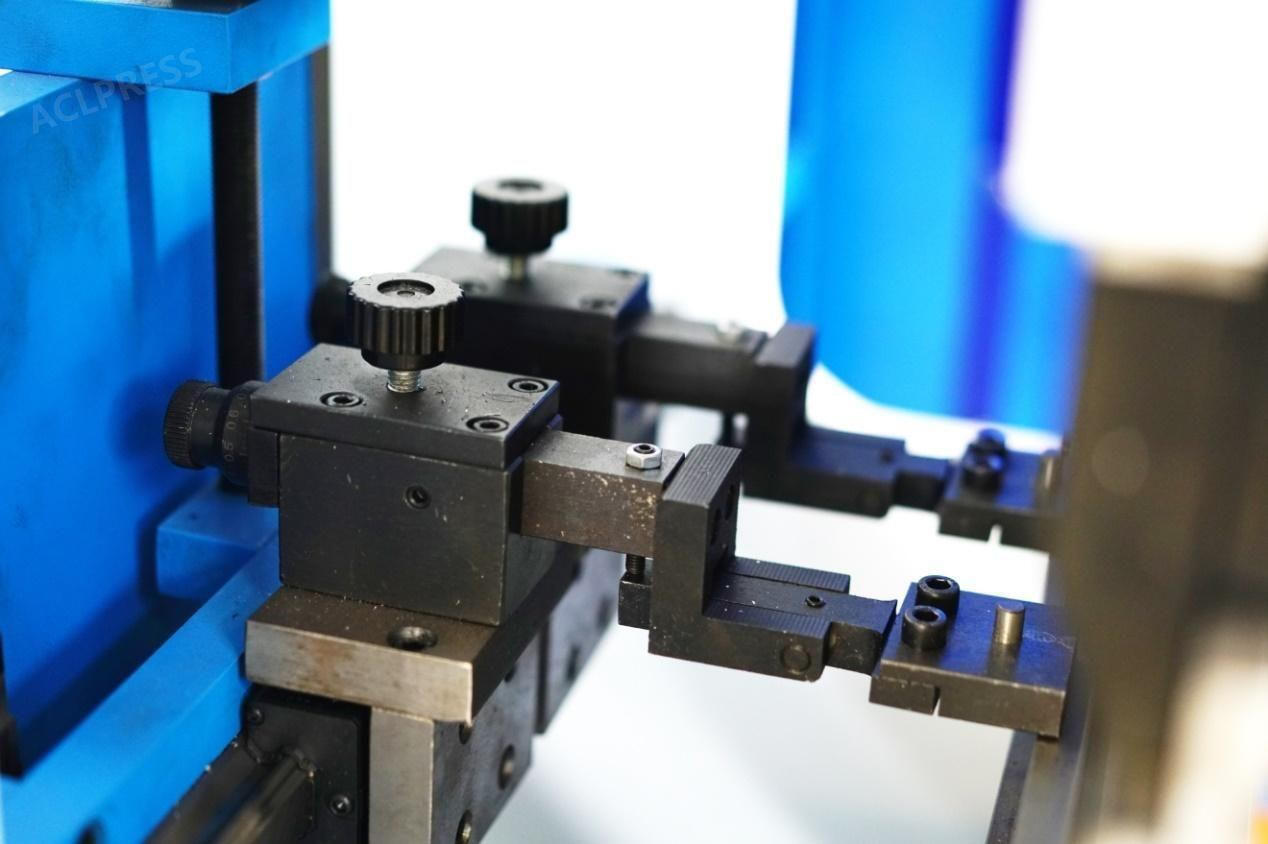

CNC BACK GAUGE

Bukmachines zijn uitgerust met een achterste gauge die bestaat uit een solide structuur om de beste herhaalbaarheid en hoge precisie in aspositieering te garanderen.

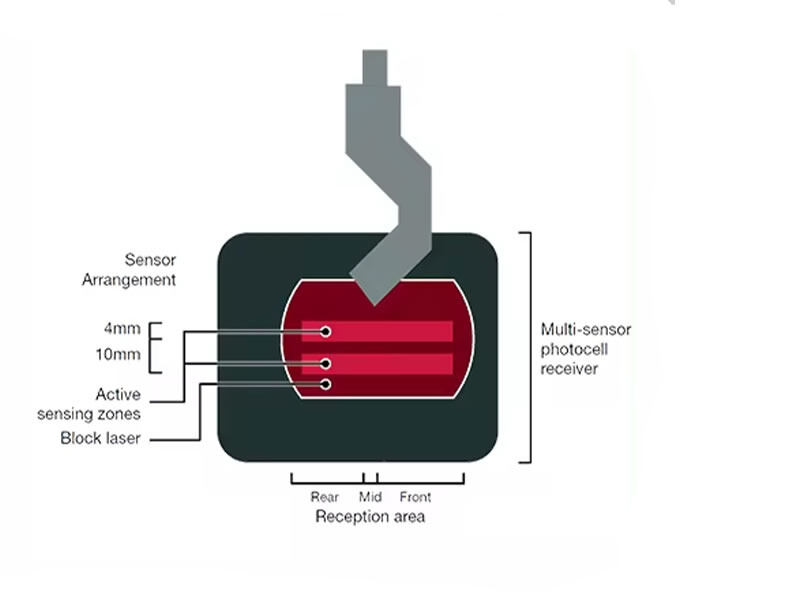

LAZERSAFE OPTISCHE VEILIGHEIDSSCHermen

Prestaties zonder compromissen. Het gebruik van het LazerSafe LZS-LG-HS-beveiligingssysteem biedt een zeer effectieve oplossing voor zowel de veiligheid van de operateur als de productiviteit van de machine. Ontworpen voor gebruik met de PCSS A-serie van Lazer Safe, voldoet Lazersafe aan categorie 4 en voldoet aan de strengste internationale veiligheidsnormen (CE-gecertificeerde categorie 4 veiligheidscontroller met geïntegreerd).

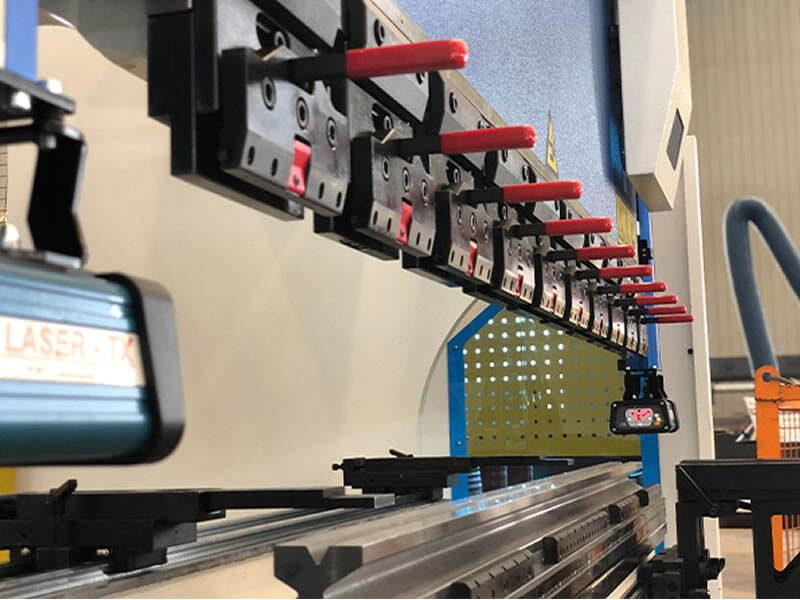

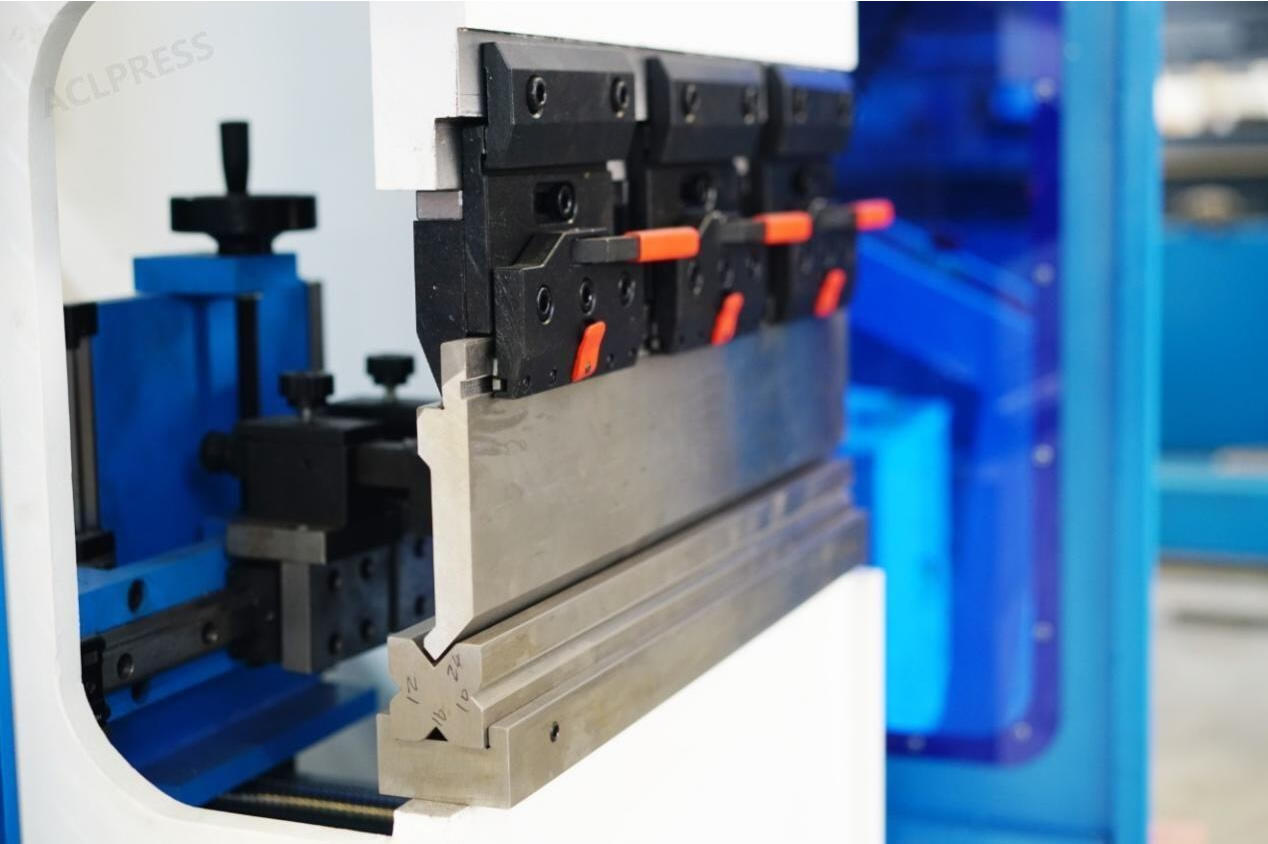

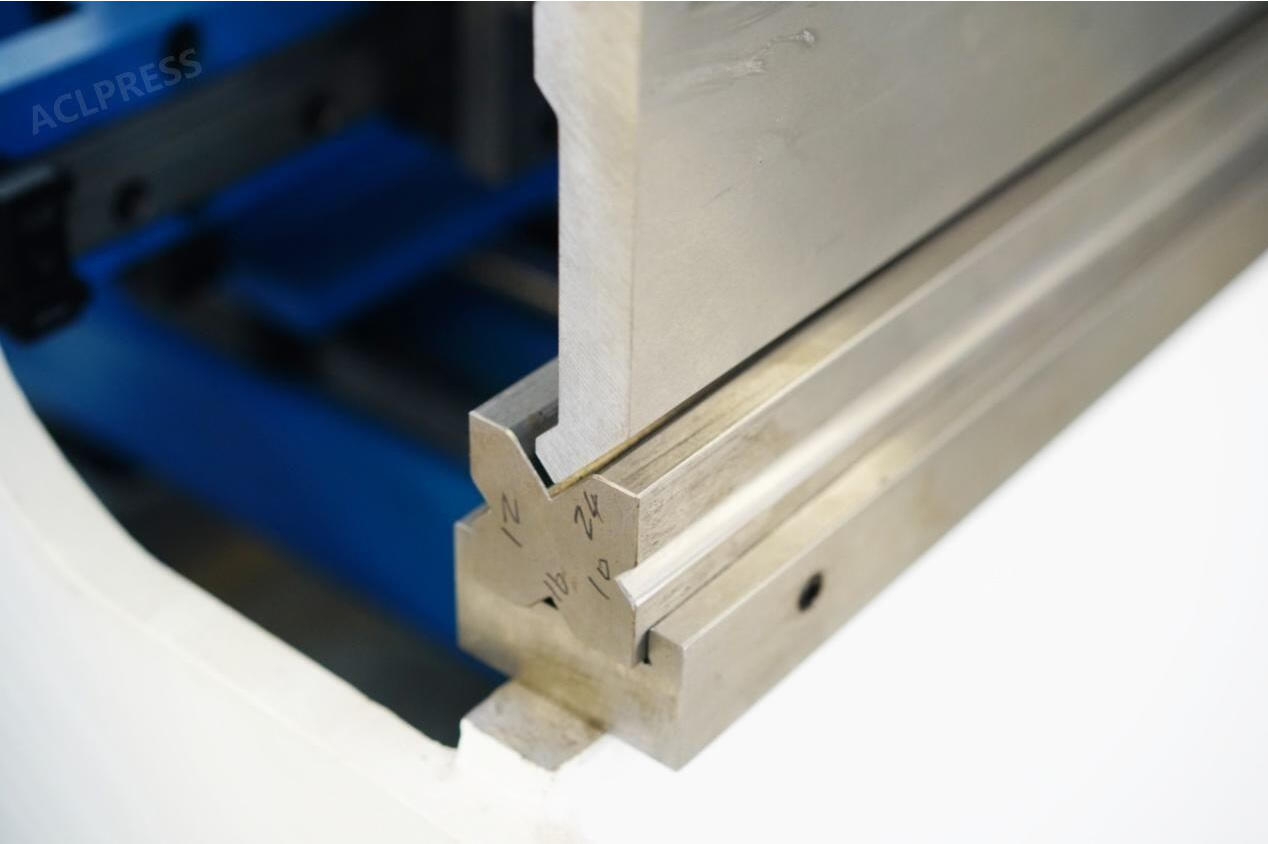

SNELKLAMP SYSTEM

- Veilig en snel wisselen van gereedschap.

- Aanzienlijke verbetering in tijdsverbruik en gerelateerde kosten.

- Beveiligd tegen gereedschapsval.

- Beschikbaar in handmatige, pneumatische en hydraulische modellen.

- Montage: Eenvoudig van onderen in de behuizing, aandraaien - KLAAR!

- Makkelijk te monteren op uw bukmachine.

- Het aanpassen van de cation van de vouwpers is niet nodig.

| BGA | x | r | Z1 | z2 | X2 |

| Slag(mm) | 750 | 150 | ONDER VERZOEK | ONDER VERZOEK | 190 |

| Snelheid(mm/s) | 500 | 170 | 2000 | 2000 | 200 |

| Nauwkeurigheid(mm) | +0,02 | +0,05 | +0,05 | +0,05 | +0,02 |

| Type motor | BRUS HLESS | BRUS HLESS | BRUS HLESS | BRUS HLESS | BRUS HLESS |

| Mechanisch systeem | Schroef | Schroef | RACR | RACR | Schroef |

EN

EN

AR

AR

NL

NL

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TR

TR